gratte-tout

Well-Known Member

- Joined

- Jan 28, 2008

- Messages

- 166

Last news :

I received the rest of the parts needed from Tower, 2 "Y" wires with a switcher, rpm sensor and T° sensor for the eagle tree system (e-logger V3), the e-logger should come next week.

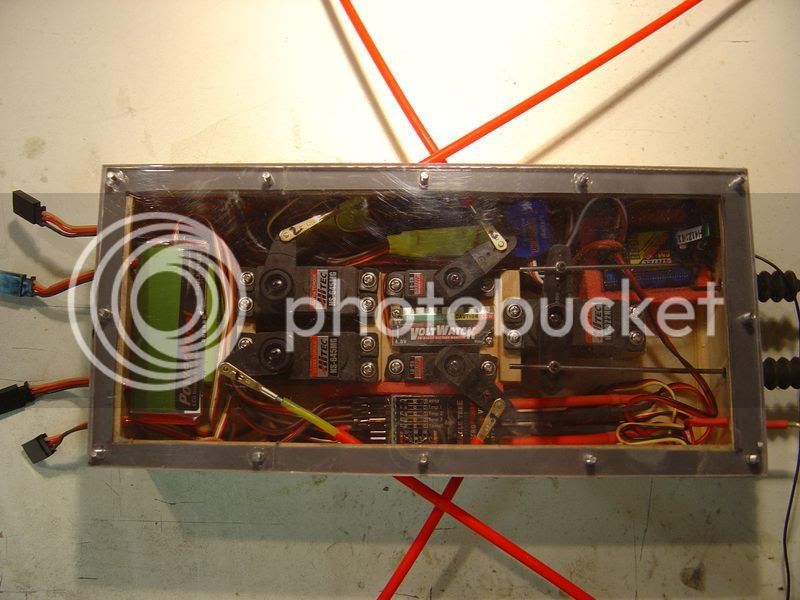

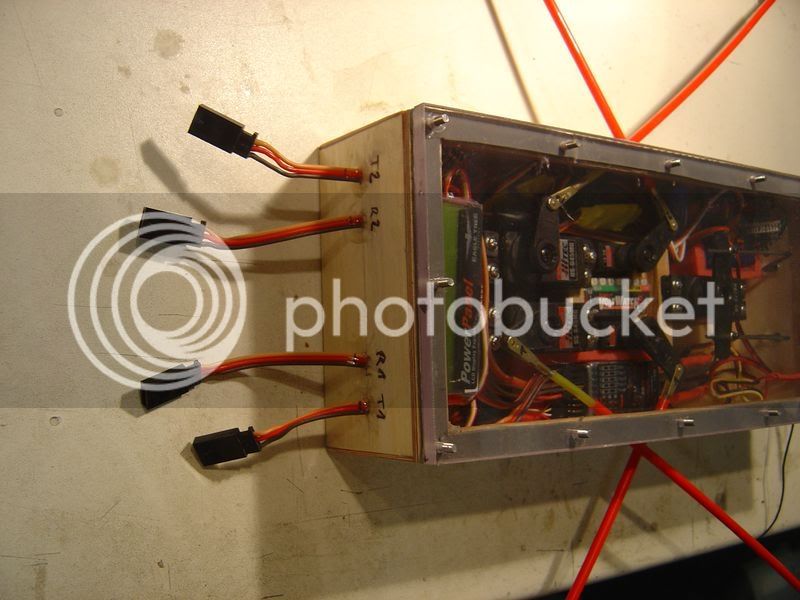

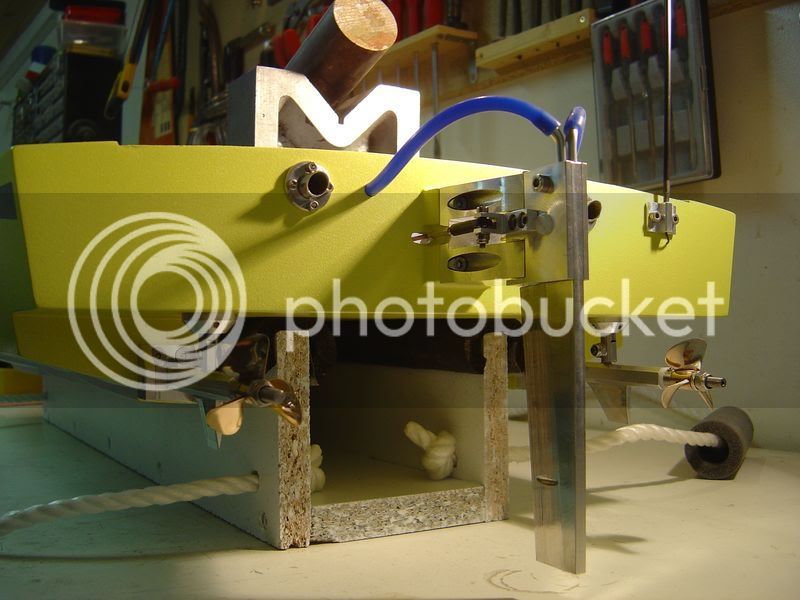

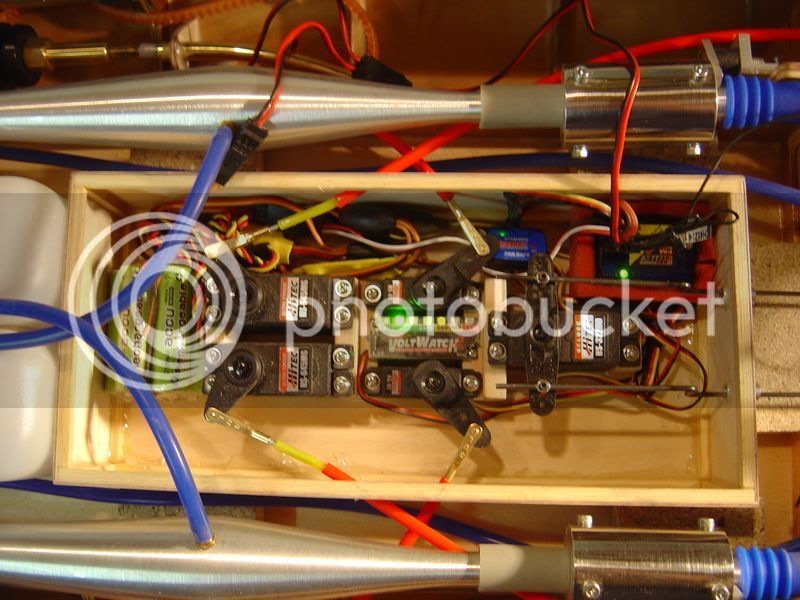

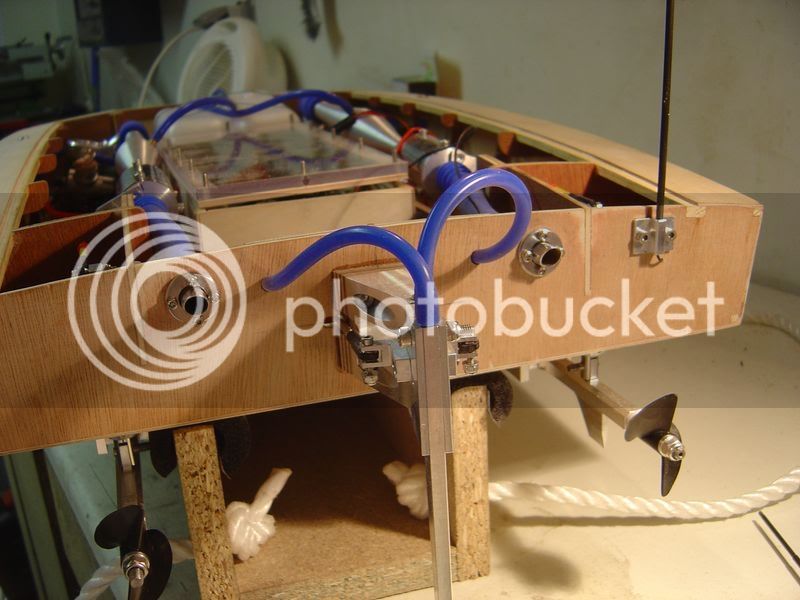

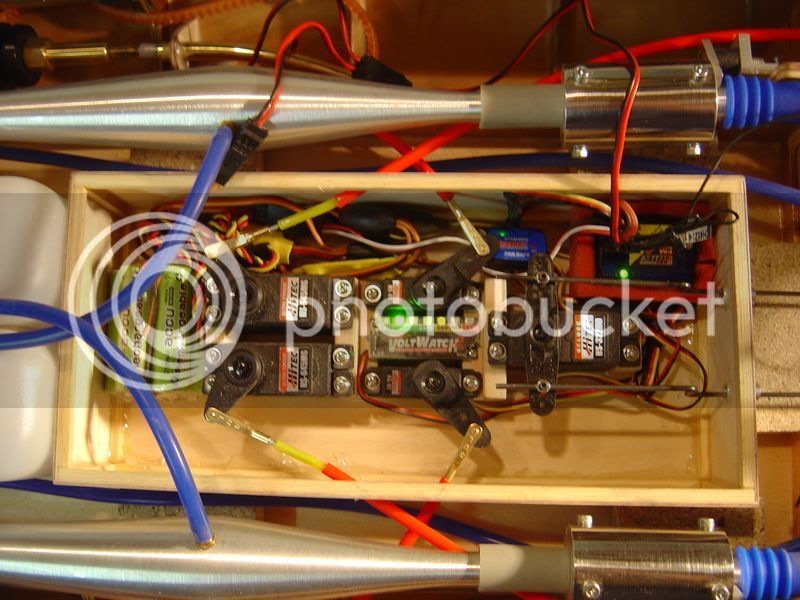

The radio bow starts to be more clean :

I machined a little bracket to hold the rpm sensor :

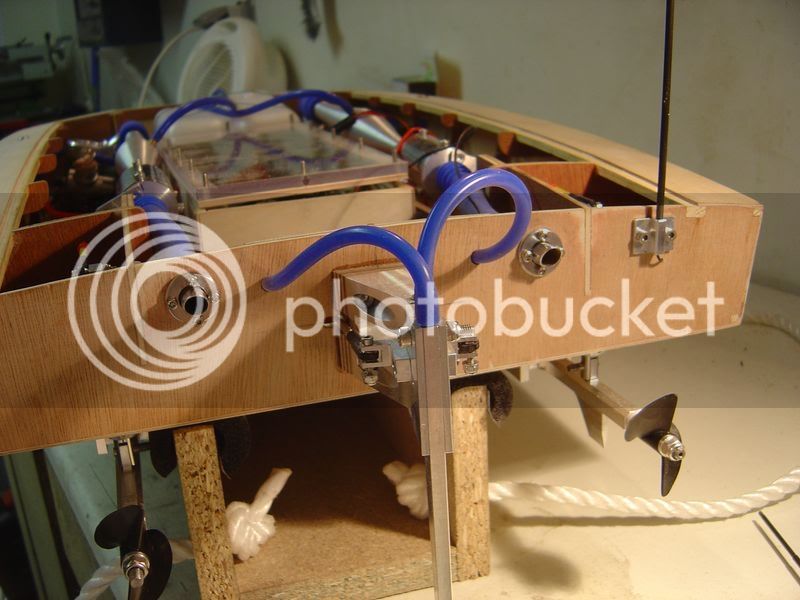

I also machined exhaust outlets, try to be as more as possible "scale"..

Why biyuing a antenna mount, when you can machine it? B)

To glu the two magnets per flywheel, and because I don't want to unscrew the setted vice on my milling machine, to put the direct divisor, I machined a little tool to dril two Ø3.2mm*1.5mm holes for the magnets.

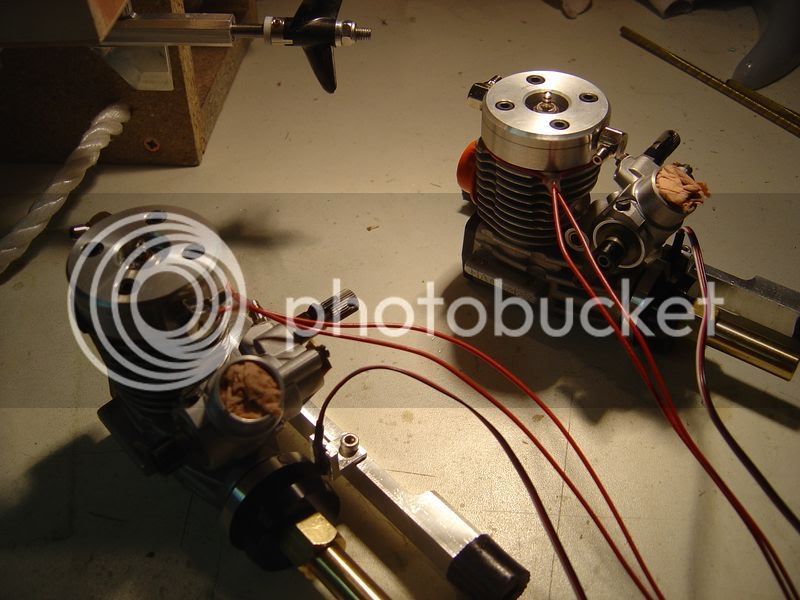

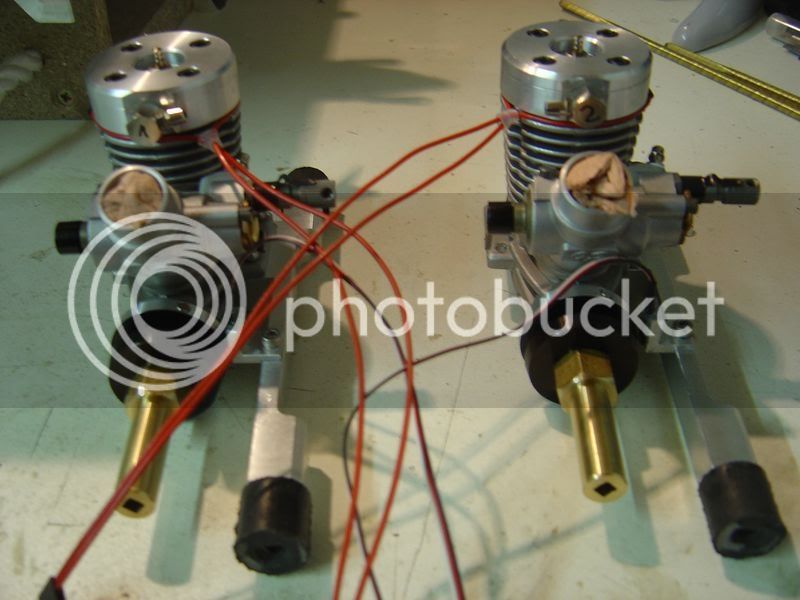

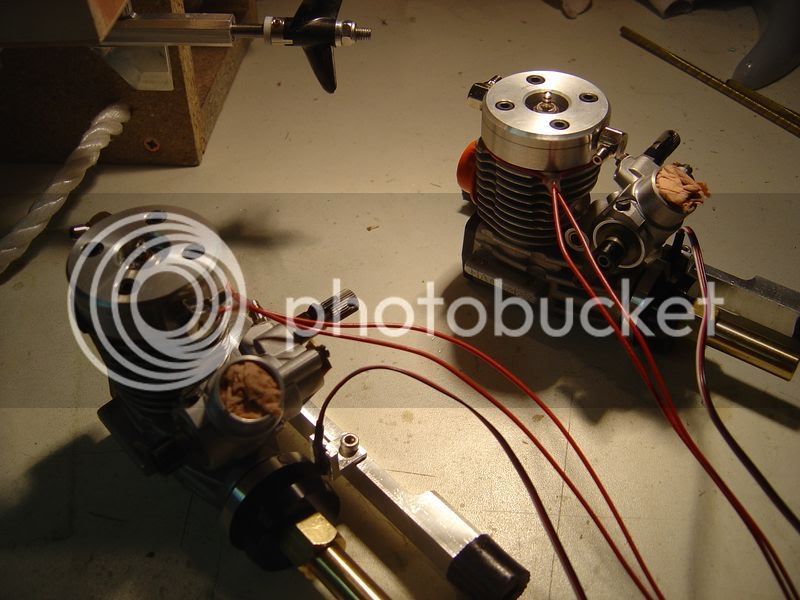

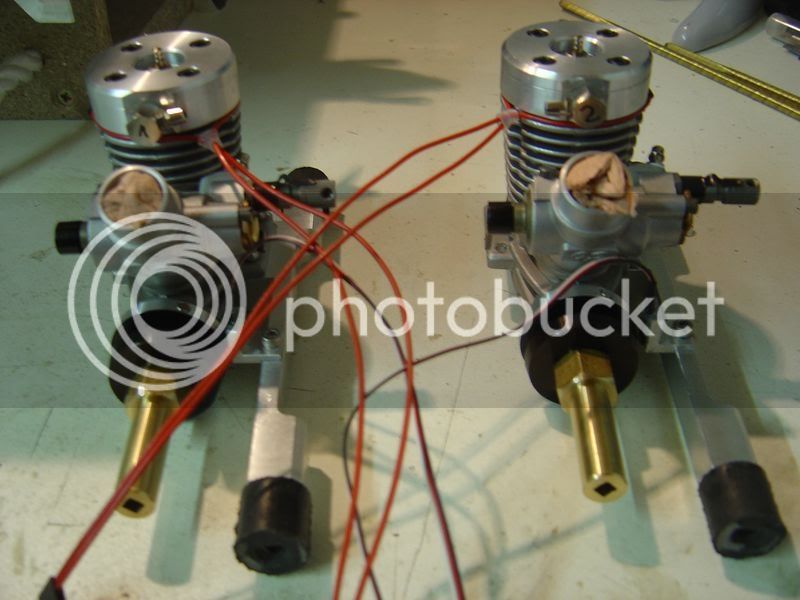

Engines with the sensors (T° and rpm)

To be continued.

I received the rest of the parts needed from Tower, 2 "Y" wires with a switcher, rpm sensor and T° sensor for the eagle tree system (e-logger V3), the e-logger should come next week.

The radio bow starts to be more clean :

I machined a little bracket to hold the rpm sensor :

I also machined exhaust outlets, try to be as more as possible "scale"..

Why biyuing a antenna mount, when you can machine it? B)

To glu the two magnets per flywheel, and because I don't want to unscrew the setted vice on my milling machine, to put the direct divisor, I machined a little tool to dril two Ø3.2mm*1.5mm holes for the magnets.

Engines with the sensors (T° and rpm)

To be continued.