B

BB Mods's

Guest

Yes if you make some shims that go under the neck of the sleeve, you will change the location of the ports in relation to the crankcase, you need to do a few things if your serouis about building a hot cat, If you dont want to go any further then shiming the sleeve up a little thats fine but wont be the best these motors could do... If you want the easy way out.. Buy 2 x CMB 21RS motors, or 2 Novarossi Plus 21-5's..

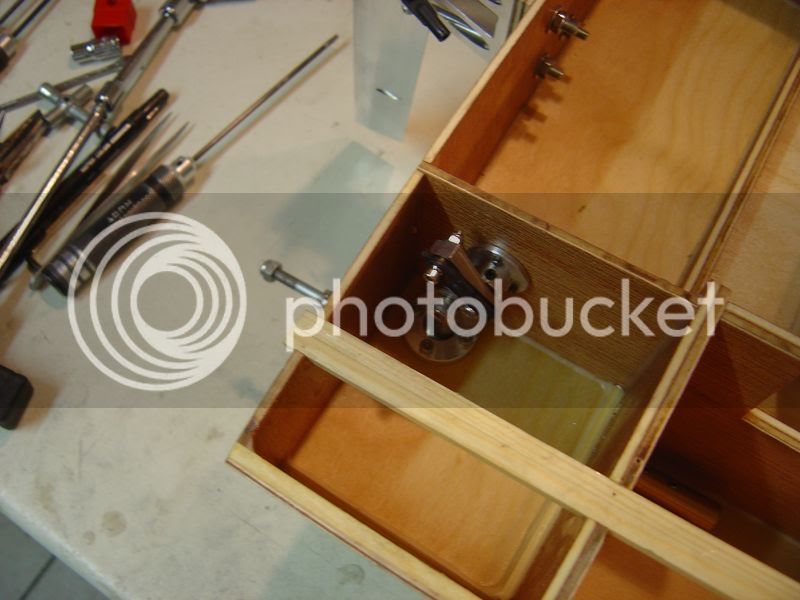

But these motors look to have some potential, could you post pics of the internals? like internal shots of the crankcase where the sleeve goes, Con rod, crankshaft, carb measurements and current port timing numbers and squish height, we might even get into bowl shape and volume seeing as how you have access to the tools to do some of this work, and would further your education into how these motors work. PM me if your interested.

BTW, Id try it anyways with .010 worth of shim and shorten up the pipe a little more

Umm.. What pipes are you running??

But these motors look to have some potential, could you post pics of the internals? like internal shots of the crankcase where the sleeve goes, Con rod, crankshaft, carb measurements and current port timing numbers and squish height, we might even get into bowl shape and volume seeing as how you have access to the tools to do some of this work, and would further your education into how these motors work. PM me if your interested.

BTW, Id try it anyways with .010 worth of shim and shorten up the pipe a little more

Umm.. What pipes are you running??

Last edited: