about 20-30 mins

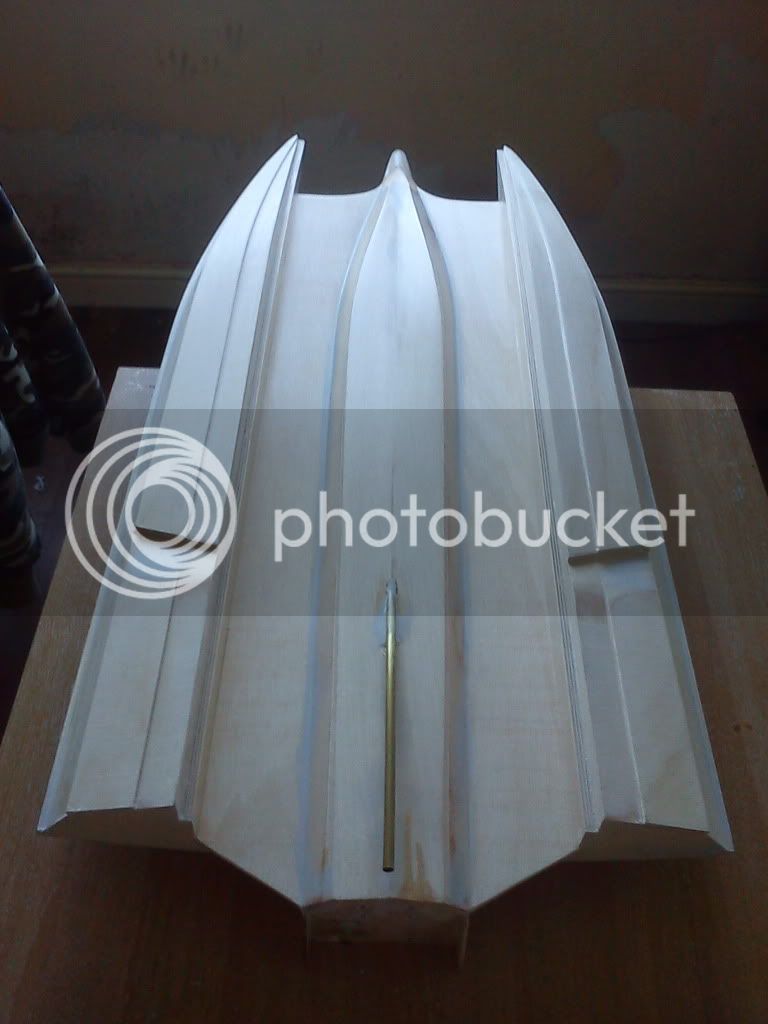

cos is waterbased what i do is thin some down for 1st coat only need a drop of water for 1st coat leave it to fully cure then give it a light sanding down.

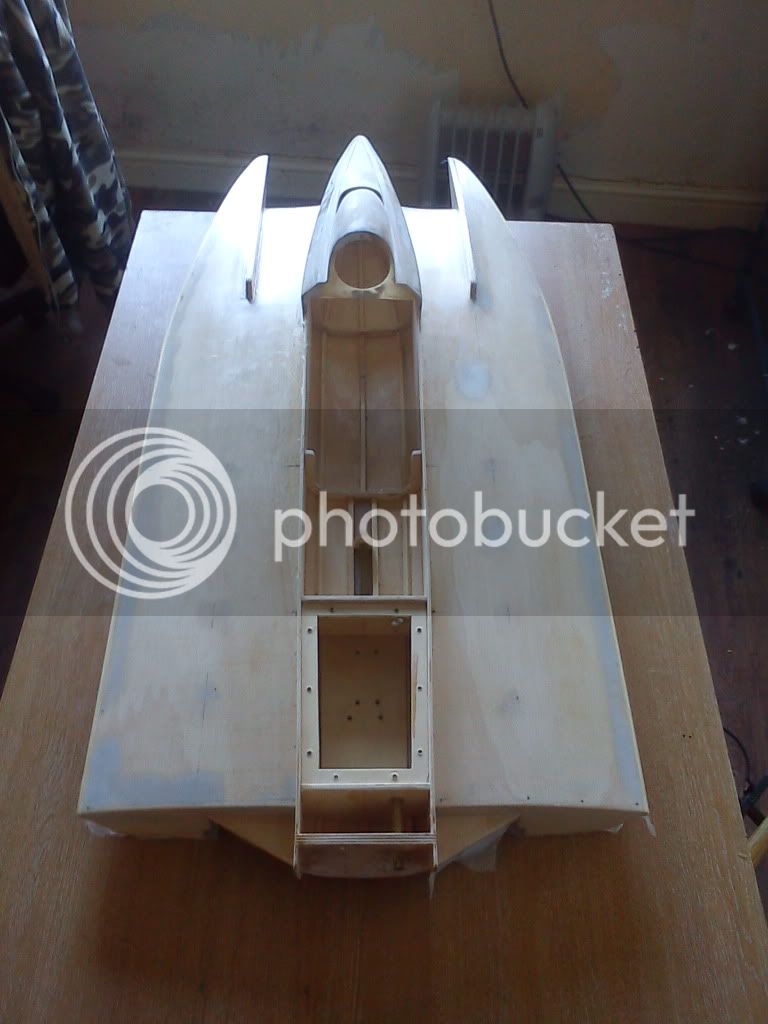

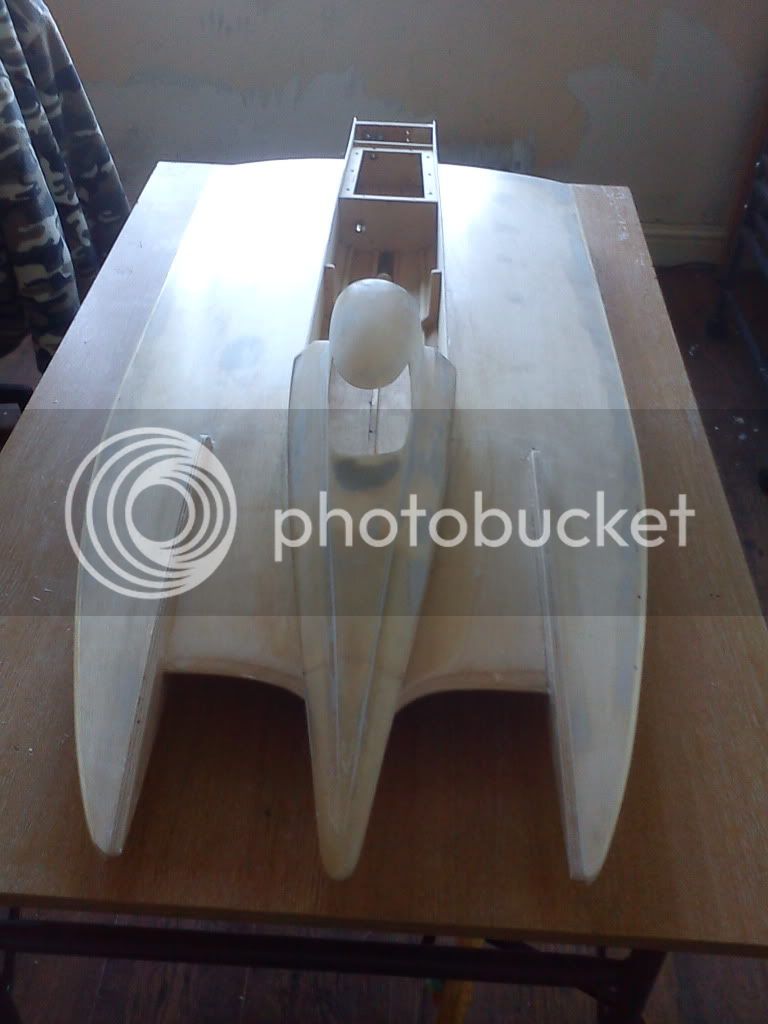

then lay the glass cloth over the hull,i use 0.6 oz as its goes down well and really workable into or round the corners or awkward areas, use quality nylon brush then start brushing the sealer on ( but i dont thin it this time) leave the edges make sure you get all the edges,any internal corners use an old credit or bank card and press it in to the corners.

Once done a cured the edges that are over hanging use a wooden block with some 320 grit and gently rub edge,this removes the over hanging material but remember you dont need to do it to much.just literally 1-2 light rubs in 1 direction.

then once all the excess material removed repeat process till the whole hull is covered.

once the whole hull is done i leave it over nite then give i a light rub down all over ready for final coat,this way youve got enough on to completely fill the grain and a nice smooth finish to primer to.

more pics soon