"Dasboatman,

Where would I pick up some of that ply you're talking about. I was thinking of some 1/4 play I have and shaving it down to match the existing thickness. The Hobby shop here only stocks balsa."

Hey Kevin,

Sorry about the delay. I don't spend much time on here and I just read this.

I get ply from National Balsa www.nationalbalsa.com. They sell aircraft grade birch plywood, basswood, hardwoods, epoxy, CA glue and many other supplies we use on model boats. I think HJ has a source out in your area. Have a look at the National Balsa site for ideas. That's why I suggested 3/32" thick birch 5 ply Shaving ply is not an easy job - laminating thinner material is, using epoxy for makimg thicker pieces, and still having the thinner material for other jobs. I usually buy 3/32" 5 ply. 1/16" 3 ply, and 1/32 " 3 ply birch ply all 12" wide X 48" long, some 3/8 and 1/2" square bass wood sticks - all 48" long, Don Smith Slow cure epoxy kits and a small CA glue from them to build with. Keep in mind that I only build boats Wood Over Foam (WOF). Building framed construction is a different critter. Their prices are a whole lot better than buying similar material from your LHS - if they even stock ply. I had done business with Lone Star Balsa www.lonestar-balsa.com for years until they had a fire some years ago. They no longer stock the 12" wide X 48" long ply I use, so I found National Balsa. I have been using them for the last 4 years or so -since my Lone Star stock ran out. Other companies would be: Balsa USA www.balsastore.com, Aircraft Spruce www.aircraftspruce.com prices vary place to place. Quality and price are alway subjective.

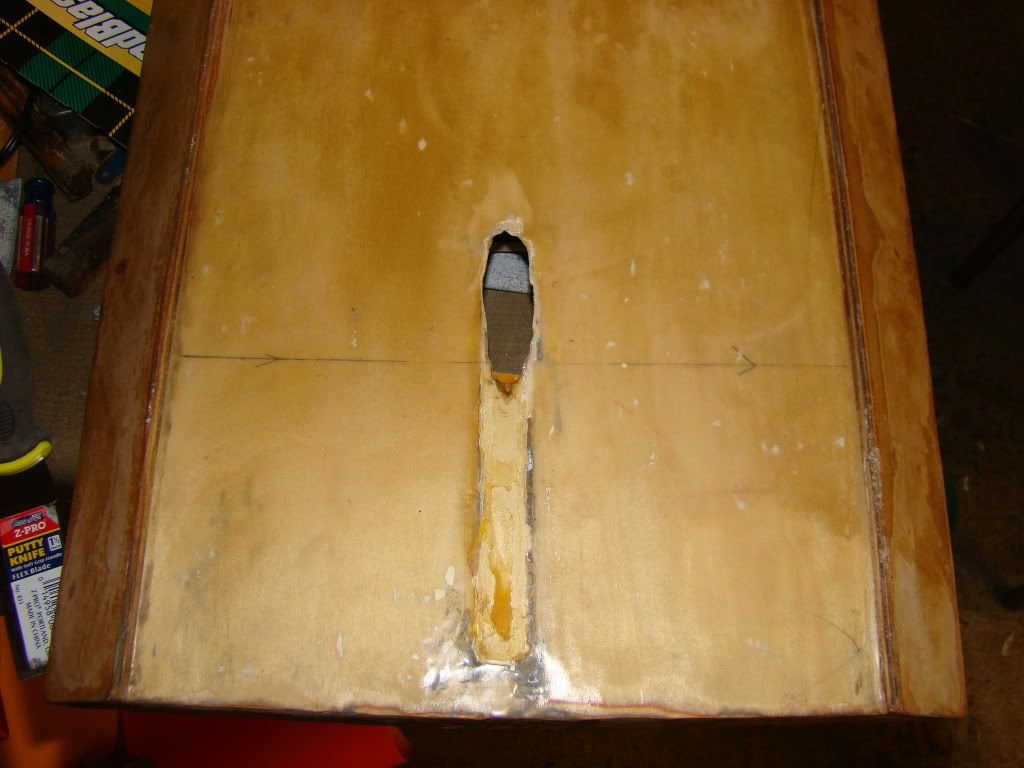

Look in the Manufacturer/Distributor For Sale Section of IW, Under 1/8th Laser cut Scale kits for sale. Mike has taken many of Roger Newton plans modified them through Computer Assisted Drafting (CAD) and has kits made up pieces are all laser cut out of aircraft grade spruce - (Pic Attached). He has kits for many different Unlimited Hydroplanes available. Heads and shoulders above the Dumas kits. If you build from Roger's plans, you will have a lot of work ahead of you just to cut out all the pieces. Once that is done and you start assembly, I believe you'll find some "tweaking" will be required to line things up. Mike's laser cut kits have corrected most of the drawing/alignment errors I believe. Mike builds electric 1/8 Scale boats. I am looking forward to someone doing a build thread using one of Mike's kits to build a 1/8 Nitro Scale. It will require some changes to the kit - tailored for nitro engines.

It is my opinion that you would have higher probability of success building one of Mike's kits. Mike has also posted a lot of build threads on here that would be of assistance to you. I have seen too many boaters completely turned away from Scale boating because of some of the junk on the market - Thunderboat Reproductions comes to mind. CHEERS !!! Bob

Posted 10 July 2010 - 12:49 PM

ML Boatworks,

Laser cut Scale Hydroplane framing kits for over 40 different hulls. Offering 1/8th scale as the base scale with other sizes coming as time permits. These kits are based on the Newton drawings with improvements being made to ensure correct fitment of every frame, crossing point, and modifications being made to the ride surface as required. Custom modifications can be made if requested for a small fee. The basis frames make a variety of different boats based on the master hull roster #'s. If you are uncertain of a particular hull, please ask, or view the master hull roster and see if the kit you are needing is one of the hulls I have done. The named hulls below are just a sample to what some of the kits make! Kits do vary in price depending on the complexity, so please ask here, PM, email at

[email protected], or call Mike @ (252) 717-6282

NOTICE: STARTING MARCH 24th, 11, I will only be accepting money order, checks or cash. Done with Paypal!

Printable MS Word Document with all kits

Finished Framing sets.doc (77K)