Craig,

Are you bolting a 101 RS in that boat? We used blocks of

metal like that 20 years ago. :unsure: The stock mount or a plastic

mount is all you need. You are going to have a 10 lb. 21 Hydro

when you get her done. On the stock mount all you need to do is glue

in some threaded rod inserts and you can bolt it right in. The JAE

team will be disappointed seeing the boat built like the 1980's. You

are going to need a 45 motor just to launch the anchor/motor mount.

I hate to be critical, but that is not how the boat was designed to run.

Good Luck,

Mark Sholund

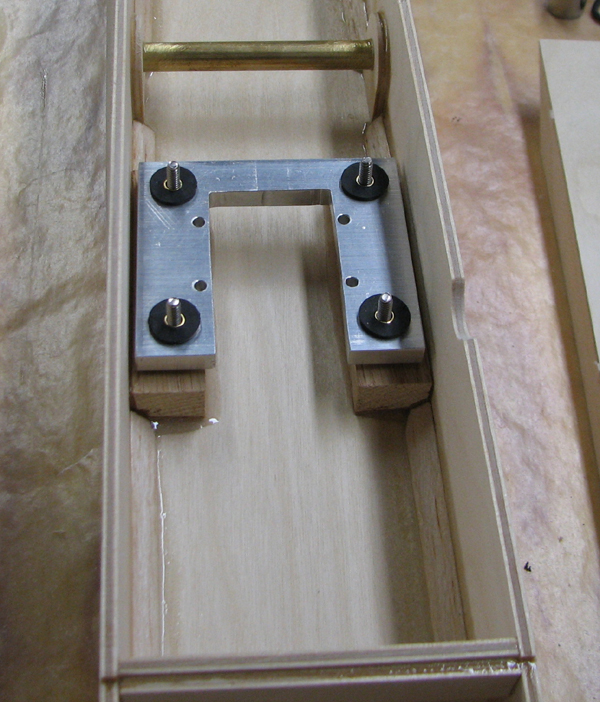

It's 1/4" thick and weighs 45 grams, not sure if that is too heavy. I can drill holes to lighten, but I wanted the 1/4" thickness for a larger bearing surface for the rubber bushings. If the mount was any thinner I would need to trim the rubber bushings.

Also, I dislike two-piece vibration damped mounts. I know, everyone is running them with no problems, but it's just me.

Not sure what you mean by "stock" mount, none was included in the kit.

I built this mount for next to nothing, as I had all the materials on hand already. All the little things add up and the next thing you know you are over budget.

Also, if it was an 80's mount there would be no vibration damping.