f41stryker

Well-Known Member

- Joined

- Jun 6, 2006

- Messages

- 510

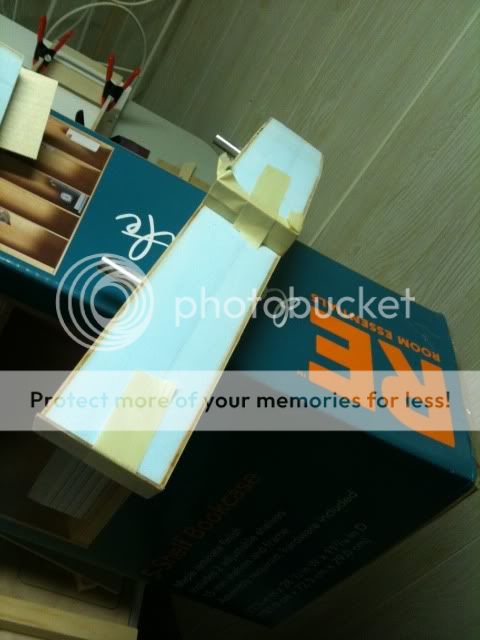

According to directions the jig was only needed for attachin the bottom which I did. I also left it in the jig while adding transome doubler and the front nose block mount. In the meantime I've been doing sponson work. Built the servo mounts. As soon as the tub is out of the jig Im going to assemble the ski.