camaroboy383

Well-Known Member

- Joined

- Feb 25, 2008

- Messages

- 2,833

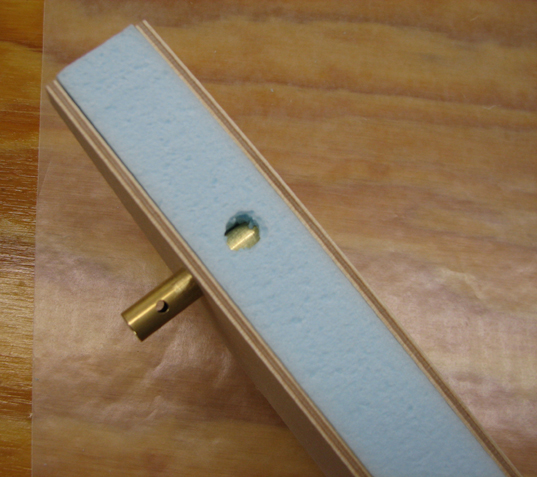

went out the other day and had a great day of runnin the trusty jae .12....... well i had noticed a sponson was sitting funny so upon inspection i had noticed the left sponson had the front aluminum tube pulled out... they were epoxied into the sponsons when it was built...

well now that the hull is painted,,,what is the best way to go about repairing this without comprimising the paint????????

im looking for somthing permanent here,,, not a band aid... but,,,but,,,any and all suggestions welcomed... id hate to have to ruin the perdy paint......lol

thanks in advance for your replys,,

Alden

well now that the hull is painted,,,what is the best way to go about repairing this without comprimising the paint????????

im looking for somthing permanent here,,, not a band aid... but,,,but,,,any and all suggestions welcomed... id hate to have to ruin the perdy paint......lol

thanks in advance for your replys,,

Alden

Last edited by a moderator: