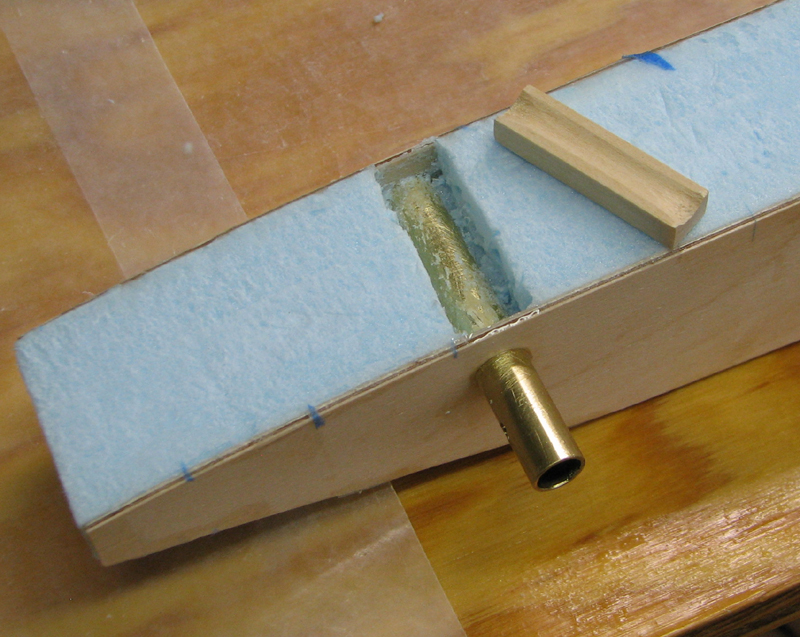

Guys, I have had really good luck with my jae and it has been run a lot and flipped and hit bouys etc....anyway what i have been experiencing is the brass tubes, although epoxied in place they tend to want to turn on me and come loose.The thing i see that is bad is that they really only get glued to the 1/8 ply in two places and the foam between the 1/8 ply formers.

I figure when you put the glue in the hole and then insert the brass tubing , most of the glue gets squeezed out of the holes in the ply and not much is left to wick into the wood and bite the brass where i have it roughed up.

The ones i have been re-epoxying , I have been extending the brass out past the outer ply and roughing it up for the epoxy to get a bite on the outside of the sponson and the brass at the same time, making an epoxy washer if you will .That seems to work.

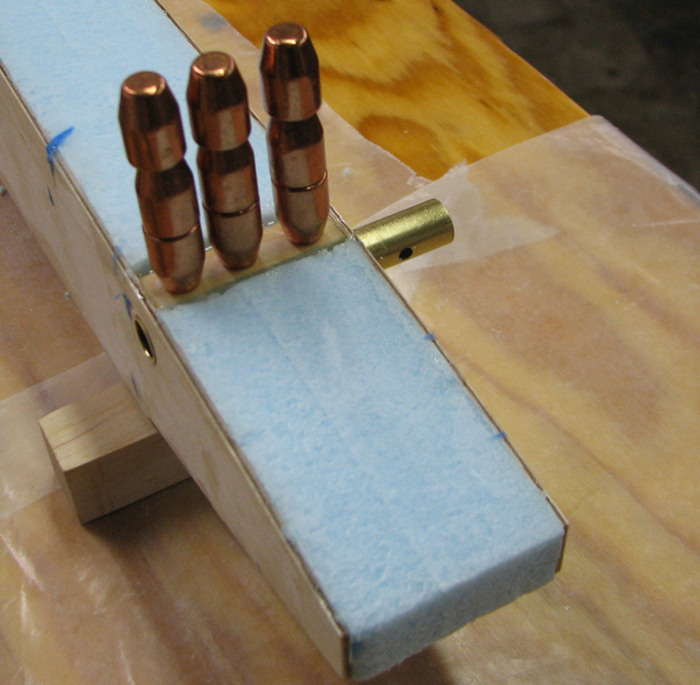

Someone at the last d11 race while they watched me repair my sponson by using ca and drilling down through the top of the sponson through the wood, foam , brass and Cf and then screwing in a 4-40 socket head cap screw(which is still in there until i do the better repair),,,,,said they saw or read on here that some people have soldered a washer on the end of the brass tubing.I would assume this was done and the tube pushed in from the outside, the washer being epoxied to the side of the sponson.

If i was doing building another set of sponsons i would make a balsa frame inside for the brass or make some doublers for inside the sponson for the area where the tubes go through Or drill down from the top and leave a cavity in the foam around the tubes and fill it with slow west epoxy.

I still could drill down from the top ,some holes and fill with epoxy since the boat is getting fresh paint for 2012.I found the Ninja green a bit hard to see last summer .

I was curious to know what you guys have done to keep the brass secure.I know of two other boats that have had the same issue.I think the load on those brass tubes is too great for such a small area of contact between the ply/foam and the brass.

Thanks for your time.

I figure when you put the glue in the hole and then insert the brass tubing , most of the glue gets squeezed out of the holes in the ply and not much is left to wick into the wood and bite the brass where i have it roughed up.

The ones i have been re-epoxying , I have been extending the brass out past the outer ply and roughing it up for the epoxy to get a bite on the outside of the sponson and the brass at the same time, making an epoxy washer if you will .That seems to work.

Someone at the last d11 race while they watched me repair my sponson by using ca and drilling down through the top of the sponson through the wood, foam , brass and Cf and then screwing in a 4-40 socket head cap screw(which is still in there until i do the better repair),,,,,said they saw or read on here that some people have soldered a washer on the end of the brass tubing.I would assume this was done and the tube pushed in from the outside, the washer being epoxied to the side of the sponson.

If i was doing building another set of sponsons i would make a balsa frame inside for the brass or make some doublers for inside the sponson for the area where the tubes go through Or drill down from the top and leave a cavity in the foam around the tubes and fill it with slow west epoxy.

I still could drill down from the top ,some holes and fill with epoxy since the boat is getting fresh paint for 2012.I found the Ninja green a bit hard to see last summer .

I was curious to know what you guys have done to keep the brass secure.I know of two other boats that have had the same issue.I think the load on those brass tubes is too great for such a small area of contact between the ply/foam and the brass.

Thanks for your time.