gratte-tout

Well-Known Member

- Joined

- Jan 28, 2008

- Messages

- 166

Hi all,

To introduce me fast : I'm fabrice, 26 yo, living in Lyon in France. I'm CAD designer, on catia V5.

I can't speak perfect english, so excuse me for mistakes I may do.

My hobbies are designing catamarn's hulls on my CAD software. I made a first one, all in plywood, mounted with an OS .61 VR-M engine. It runs well for a first shot, for the first year of test I made something like 55mph with a 1455 prop. I bought fex days ago new props, I may do better.

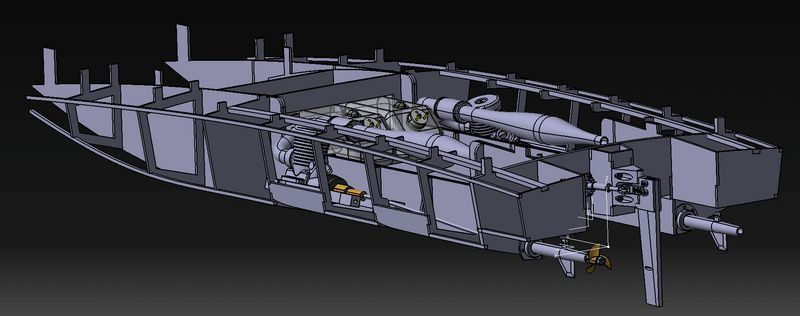

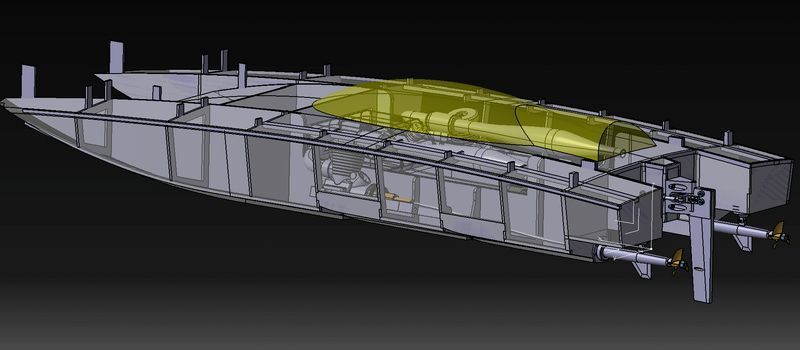

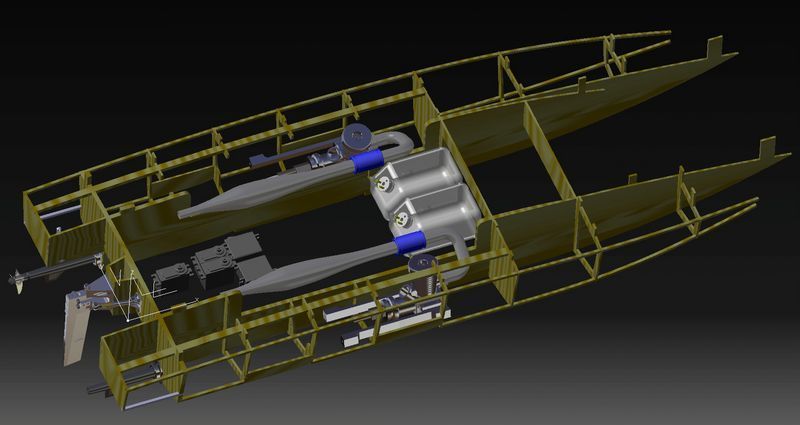

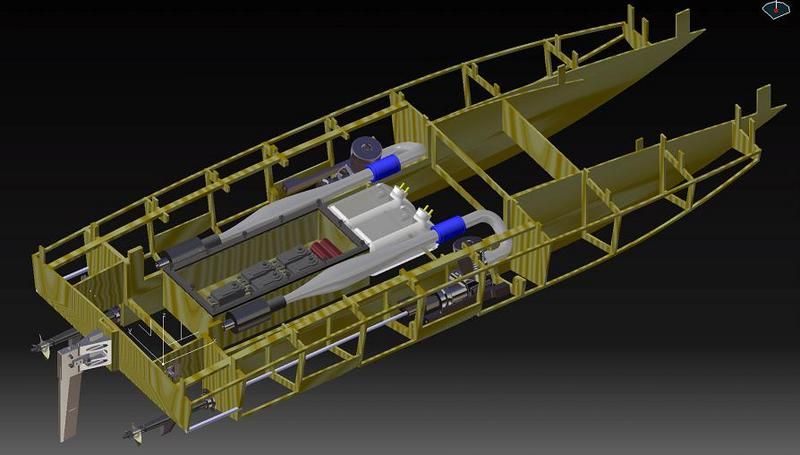

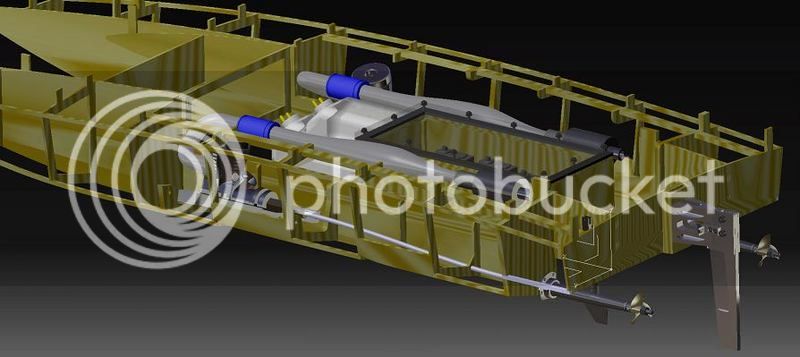

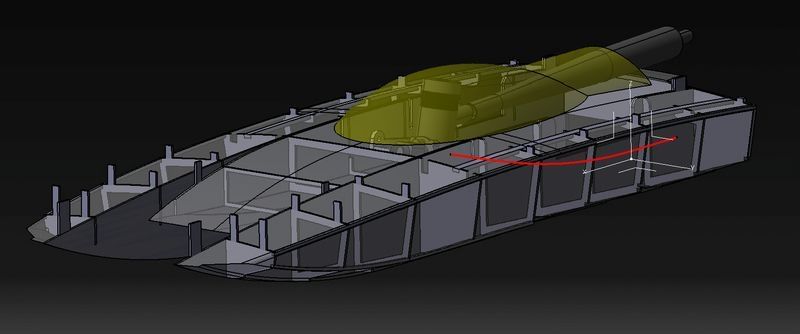

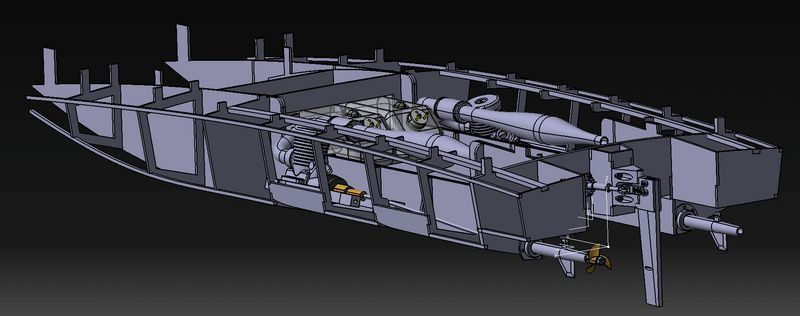

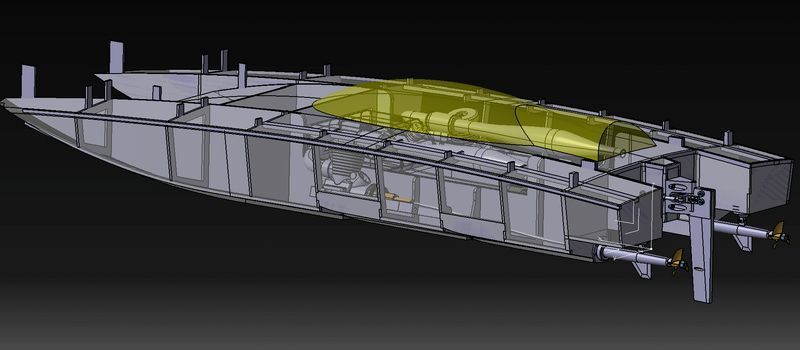

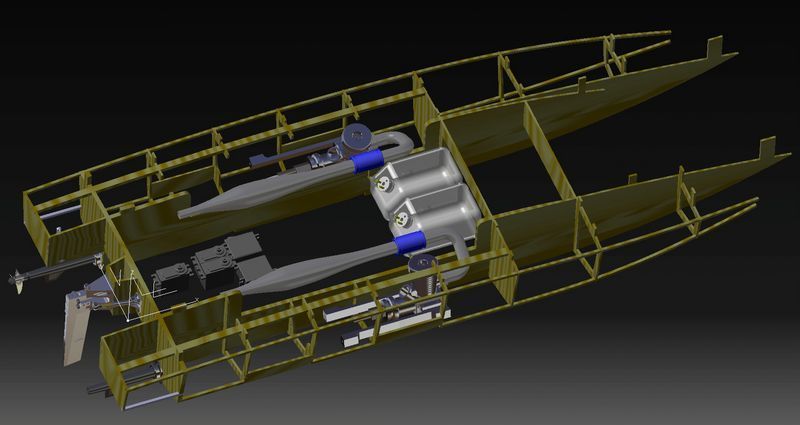

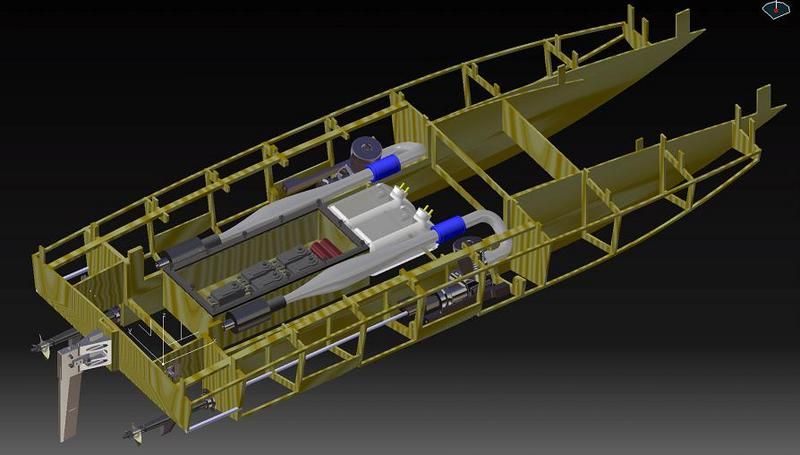

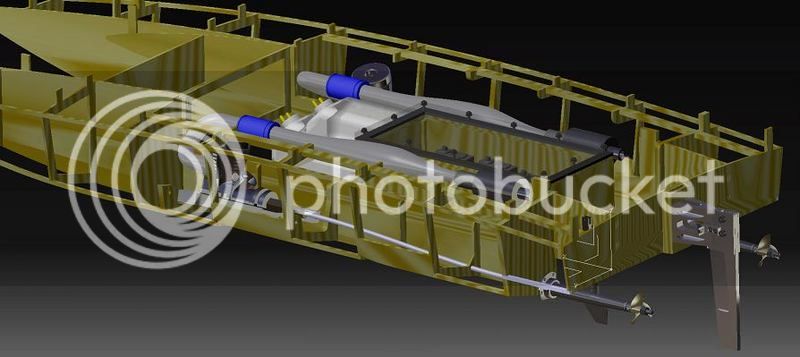

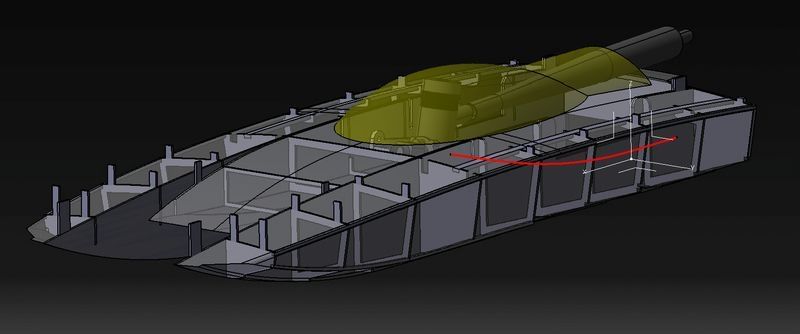

This is the CAD screenshots

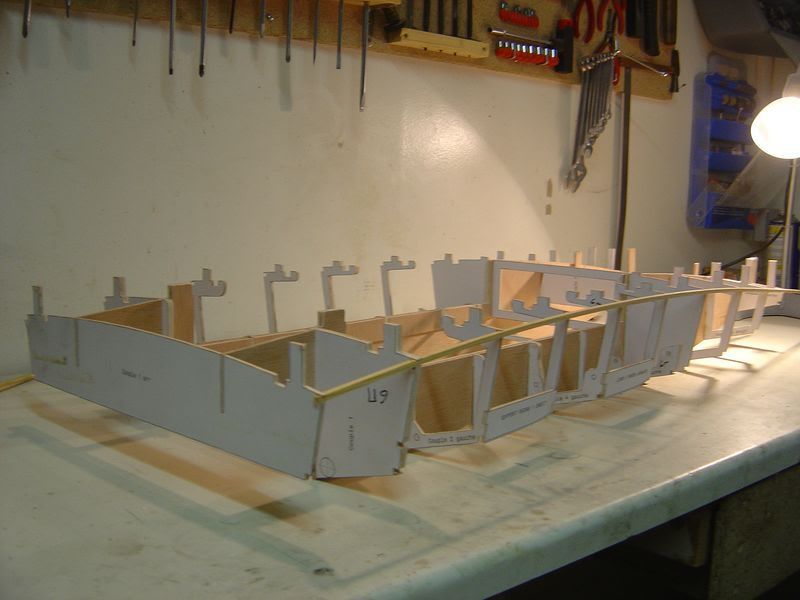

And this is the hull i made

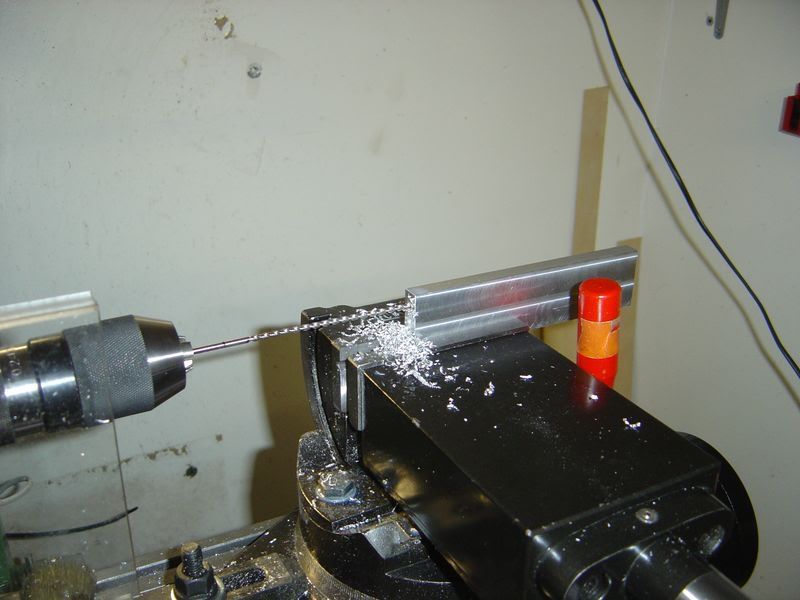

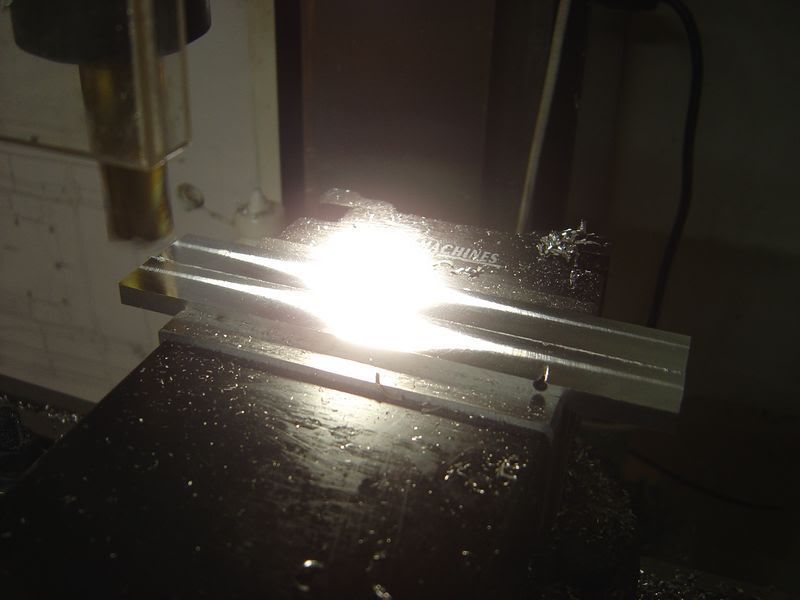

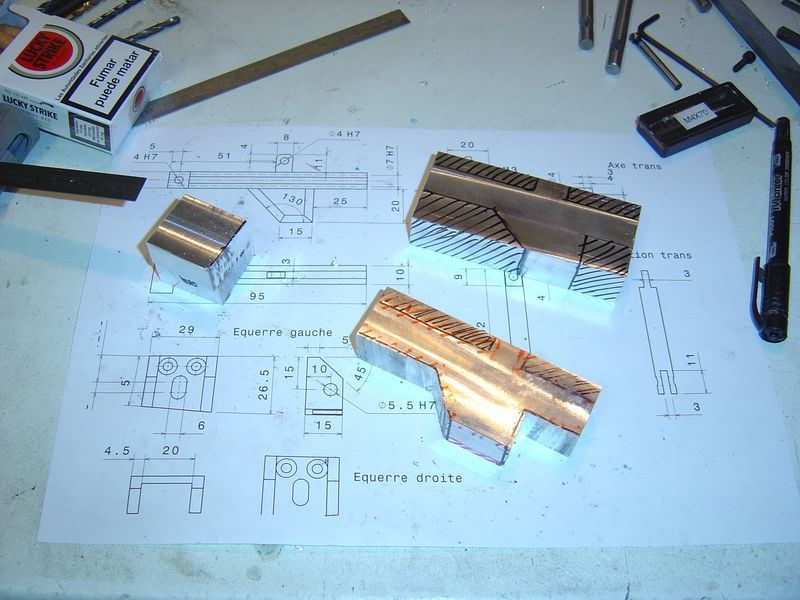

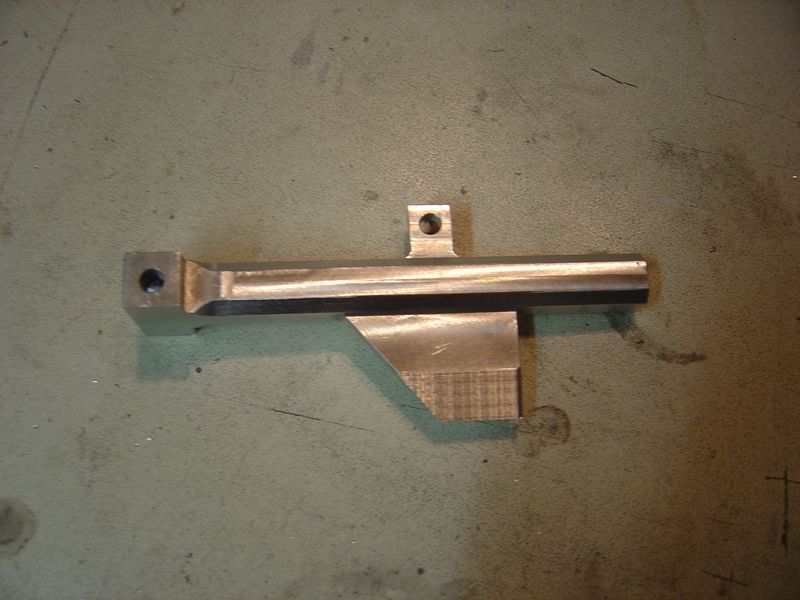

My pleasure is to do as much as I can all parts I put on my boats. As I bought few months ago a milling machine, and using a mini lathe, I try to manafacture myself parts, like rudders, engine mounts ...

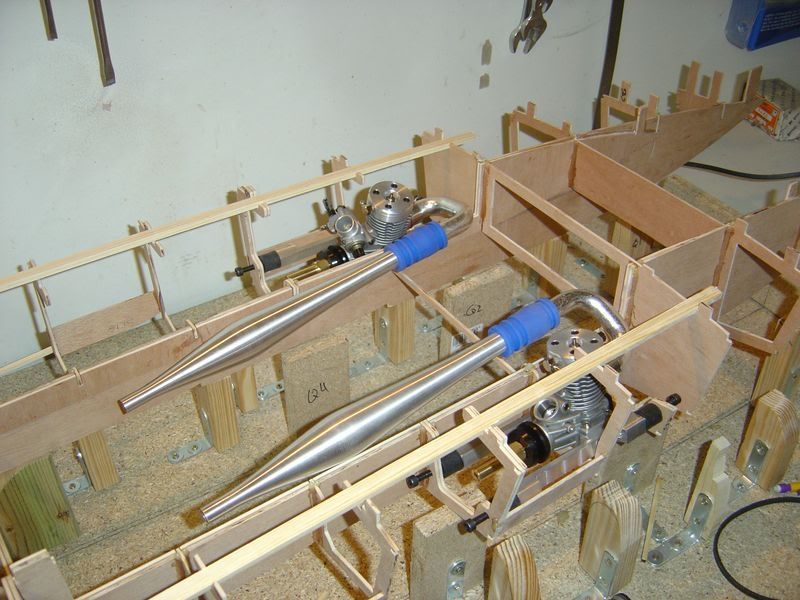

My project today is to built a hull such as the first one, but with twin nitro .21 engines.

I bought two STS D21T MKII engines, I saw manys vids on the web, they were in truggy or similar and I choose them because they seems to love high rpms..

The hull is similar to the first one, but modded to mount the two engines. I decided with friends on another forum board to install rc trims on the drives, to pilot them on water with my radio.

Here are the screenshots of the work I made on the CAD software : 180 parts designed.

To introduce me fast : I'm fabrice, 26 yo, living in Lyon in France. I'm CAD designer, on catia V5.

I can't speak perfect english, so excuse me for mistakes I may do.

My hobbies are designing catamarn's hulls on my CAD software. I made a first one, all in plywood, mounted with an OS .61 VR-M engine. It runs well for a first shot, for the first year of test I made something like 55mph with a 1455 prop. I bought fex days ago new props, I may do better.

This is the CAD screenshots

And this is the hull i made

My pleasure is to do as much as I can all parts I put on my boats. As I bought few months ago a milling machine, and using a mini lathe, I try to manafacture myself parts, like rudders, engine mounts ...

My project today is to built a hull such as the first one, but with twin nitro .21 engines.

I bought two STS D21T MKII engines, I saw manys vids on the web, they were in truggy or similar and I choose them because they seems to love high rpms..

The hull is similar to the first one, but modded to mount the two engines. I decided with friends on another forum board to install rc trims on the drives, to pilot them on water with my radio.

Here are the screenshots of the work I made on the CAD software : 180 parts designed.