- Joined

- Apr 14, 2008

- Messages

- 2,019

A little bit off topic but...

I've never seen the inside of these gas engines being run in these r/c boats (nitro fan). Are ANY of them running four bearings? If so, why???

Don't recall ever seeing four bearings in anything but four cycle engines. Most where bushings.

Yes many have four bearings. The Quickdraw, the Tiger King, RCMK engines just to name a few. For crank stability. When your using cranks with same dimensions as a 20 year old 23cc engine making 1.5 horsepower and you put it in a modified 30.5cc making over 8 horsepower. Most do it to stiffen up the assembly and keep the flywheel off the source coil. We have run 3 and 4 bearings in regular Zenoahs. To work properly the crank must have straight ends and most are tapered so the crank may not even be touching the inner race of outer bearings except when crank is flexing.

Then you need seals on top of that at each end.

The inlines run two sets of needle caged needle bearings in the center and 4 more deep groove ball bearings 2 at each end. The center section that splits horizontally is water cooled.

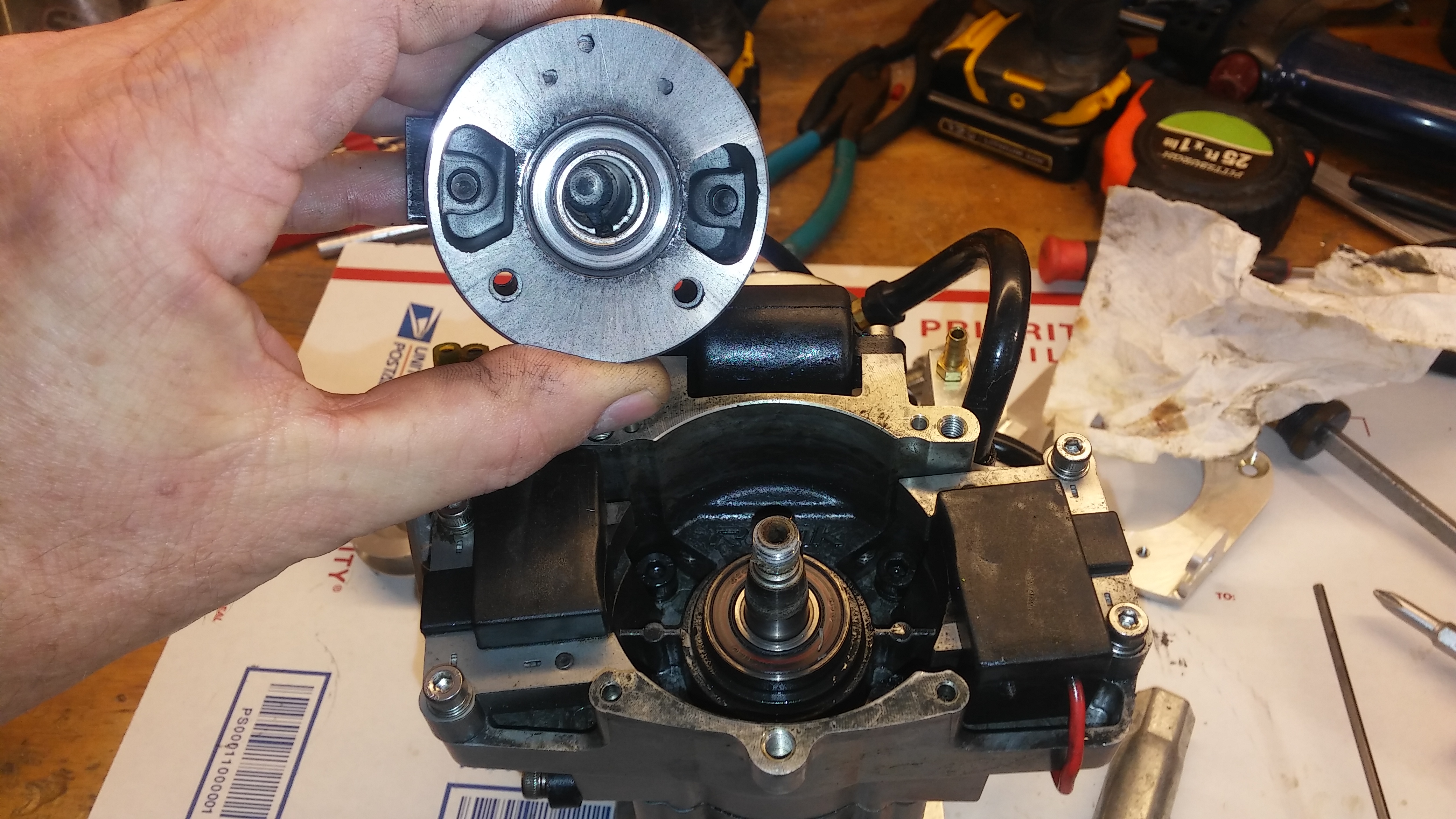

Here is a front outer bearing on a inline that decided to come out of it's bore. Unfortunately it is a little too common of an occurrence. Usually it is from factory piss poor fit and/or the fact they press them in cold. Twisted crank and overheating are two other reasons one might spit a bearing.

Last edited: