You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

piston fit

- Thread starter dwilfong

- Start date

Help Support Intlwaters:

This site may earn a commission from merchant affiliate

links, including eBay, Amazon, and others.

Joe Warren

Well-Known Member

- Joined

- Nov 29, 2003

- Messages

- 8,188

Well I was hoping that the Brass Head Button Topic would not come up till after the next couple of BIG Races!!!!! Steve is making them & I have never seen anything like them as for Performance they Provide. There is NO DOUBT that they Allow the Engine to Burn More of the Nitro Percentage that is Already in the Fuel by providing a higher heat to the prechamber. They are made out of what ever Steve Wood says they are made out of?? But the Alum ones will NEVER be back on my RS101s. & You better hope you got a pair or two for Hobart in a few weeks?? & Ralph already has some for Charleston........ Thats all I`am saying for now!! Done.....Now Back to the original reason for this thread!!!

Last edited by a moderator:

julianconde

Well-Known Member

- Joined

- Jan 22, 2009

- Messages

- 5,655

GET EM JOEWell I was hoping that the Brass Head Button Topic would not come up till after the next couple of BIG Races!!!!! Steve is making them & I have never seen anything like them as for Performance they Provide. There is NO DOUBT that they Allow the Engine to Burn More of the Nitro Percentage that is Already in the Fuel by providing a higher heat to the prechamber. They are made out of what ever Steve Wood says they are made out of?? But the Alum ones will NEVER be back on my RS101s. & You better hope you got a pair or two for Hobart in a few weeks?? & Ralph already has some for Charleston........ Thats all I`am saying for now!! Done.....Now Back to the original reason for this thread!!!

Andy Brown

Well-Known Member

- Joined

- Feb 8, 2003

- Messages

- 2,657

Interesting note. I once heard from a drag racer that " iron heads were faster than aluminum heads".

- Joined

- Apr 20, 2011

- Messages

- 2,079

Hi David,So to get back to the piston fit.

I have ordered a custom 29mm hone from Brush research.

It is a 800 grit Levigated Alumina compound. there specks for the surface finish are RA 3-10 (.05-.2 micrometer)

My intent is to polish the cylinder. Don't know how it will work till I give it a whirl. for $32 have nothing to lose testing it on old liners.

Will give it a try this weekend.

David

We used a copper plug lap and diamond dust to lap more taper in the liners, also used a jig grinder with borazon carbide wheels to get them round and add taper. You might want to consider using a support sleeve around the liner when working it.

John

Marty Davis

Well-Known Member

- Joined

- Sep 25, 2004

- Messages

- 2,445

This is sure not something that is a great test, but I saw Tommy Cardoso build a 660 brass head button for his 101 CMB. The engine and boat was MUCH faster than it had been. I have no idea what the volume comparison was with the previous aluminum button, but there is no doubt that it was faster.

I am not convinced that just the brass material is going to produce a more powerful engine. I use it because it doesn't show detonation as much.

I also make some very narrow grooves that go into the squish band from the top to allow more surface area for cooling.

Until we do some dyno testing, all of this is just a guess. Maybe we will get some time to do some side by side testing in the near future on the dyno.

I am not convinced that just the brass material is going to produce a more powerful engine. I use it because it doesn't show detonation as much.

I also make some very narrow grooves that go into the squish band from the top to allow more surface area for cooling.

Until we do some dyno testing, all of this is just a guess. Maybe we will get some time to do some side by side testing in the near future on the dyno.

Marty Davis

Well-Known Member

- Joined

- Sep 25, 2004

- Messages

- 2,445

Mr Hargett:Mr Davis im really not tyring to be an azz but if detonation is a problem and I dont know that it is in a 2 stroke why would you want to hide it? How will you know its going on to correct it.Mind you im very dumb coz I dont even understand how a 2 stroke has detonation. I thought some of its(detonation) principles are what made these type engines run. Thought thats why we used glow plugs - beacause the latent heat of the last combustion event plus the compression gave me fire for the next revolution.Im really learning something here. About the dyno Joe W tells me that some of their crews record boats times will drop because of the button change. All of them(RR CREW) are making the change. Strong statement but Joe really believes in theese things so until someone confirms it on a dyno we will have to see. One thing I do know- they are very speed greedy so if it doesnt make the boat faster they wont stay with them long.

Hugh

Simple reason that I use a brass button. I don't have replace it from detonation damage. I still have to replace the piston, but not the custom button.

Most people call me Marty

H

hugh hargett

Guest

RodneyPierce

Well-Known Member

- Joined

- Mar 26, 2006

- Messages

- 4,464

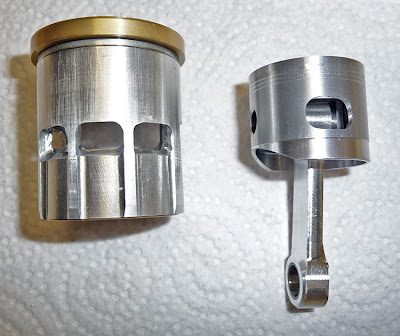

Hugh, that appears to be a standard Brass liner with chrome plating.

H

hugh hargett

Guest

Nah it not standard heres what it says " The cylinder sleeve/liner is chromed brass with an ergal aluminum sleeve as in "bimetal" heres the blog http://www.bing.com/...6911D26C3DE6F3E

that should "really" make finding the expansion rate quite complicated.

that should "really" make finding the expansion rate quite complicated.

Last edited:

RodneyPierce

Well-Known Member

- Joined

- Mar 26, 2006

- Messages

- 4,464

Good call! Awesome pictures there as well.Nah it not standard heres what it says " The cylinder sleeve/liner is chromed brass with an ergal aluminum sleeve as in "bimetal" heres the blog http://www.bing.com/...6911D26C3DE6F3E

that should "really" make finding the expansion rate quite complicated.

Last edited by a moderator:

julianconde

Well-Known Member

- Joined

- Jan 22, 2009

- Messages

- 5,655

I will try the new headbuttons should have mine on the way and we will see what it does in NOV. I WILL POST ON HERE the lap times with the regular headbutttons and lap times with the brass headbuttons.. ill keep you guys posted good thread lots of information here..

julian

julian

Last edited by a moderator:

H

hugh hargett

Guest

Oh Im sneaky too! ergal aluminum anyone?

Jim Allen

Well-Known Member

- Joined

- Jun 7, 2005

- Messages

- 1,622

Ergal is a trade name used for 7075 aluminum alloys. Other 7000 series alloys used for moulds had names such as Alumould, Alumec, etc.Lets just leave it alone youre sneaky Julian extremely!! But im watching ya move in the shadows. :huh: .

Jim , Marty, Andy, someone lets go back to the ops. Whats "ergal" aluminum and what were they trying to accomplish with the P/L here if anyone knows?

Maybe they wanted to change the expansion rate at the engines operating temperature.

H

hugh hargett

Guest

Jim based on whats been said here is it a fair statement to say that with the right combination of materials you can get almost any expansion rate you want? though you may not be able to calculate it based on the different alloys alone you certainly can just put it together and put it on a dyno run it and see how it goes? That requires the ability to make your own piston liners and that means alot of testing . It would be a pain in an actual boat coz if it cuts off then you got to retrieve yady ya! Seems like you have to have the proper equipment and toolery to really get in to the design aspect of motors versus go fast mods.

Jim Allen

Well-Known Member

- Joined

- Jun 7, 2005

- Messages

- 1,622

Absolutely yes.Jim based on whats been said here is it a fair statement to say that with the right combination of materials you can get almost any expansion rate you want? though you may not be able to calculate it based on the different alloys alone you certainly can just put it together and put it on a dyno run it and see how it goes? That requires the ability to make your own piston liners and that means alot of testing . It would be a pain in an actual boat coz if it cuts off then you got to retrieve yady ya! Seems like you have to have the proper equipment and toolery to really get in to the design aspect of motors versus go fast mods.

H

hugh hargett

Guest

As you change the thickness of the plating and materials used if you go in small recordable increments you can map dyno results excel it find a function or a correlation with materials if there is one - then make predictions .Just a way to head in the right direction with datalogging and dyno pulls!!! Even with the right tools if you dont know how to properly extract the info you want its all useless. I promise you school and books are good for something.

ALOT OF TESTING more than "racers" have time for. My only IMHO - Racers race let engine "BUILDERS" build just my .02 I trust a good reliable motor on a dyno that has been subjected to numerous test and material variations to do just fine in a good boat dont you?

Jim just make sure you bring the stalker and ill bring the hd camera when we hit falls lake.

How do you stop the detonation? higher nitro? still hasnt been answered here by the way!!!

Jim in the ops bi metal are you saying the outer aluminum on the sleeve is maybe a stabilizer temp wise - holds it at a certain temp- as it heats(brass) the aluminum dissipates holding it? thermal imaging would be extremely useful in analyzing whats going on.

Later

hugh

ALOT OF TESTING more than "racers" have time for. My only IMHO - Racers race let engine "BUILDERS" build just my .02 I trust a good reliable motor on a dyno that has been subjected to numerous test and material variations to do just fine in a good boat dont you?

Jim just make sure you bring the stalker and ill bring the hd camera when we hit falls lake.

How do you stop the detonation? higher nitro? still hasnt been answered here by the way!!!

Jim in the ops bi metal are you saying the outer aluminum on the sleeve is maybe a stabilizer temp wise - holds it at a certain temp- as it heats(brass) the aluminum dissipates holding it? thermal imaging would be extremely useful in analyzing whats going on.

Later

hugh

Last edited:

dwilfong

Well-Known Member

- Joined

- Jul 1, 2008

- Messages

- 5,968

My intent with this is to just get a good surface finish. Not trying to change the tapper.Hi David,So to get back to the piston fit.

I have ordered a custom 29mm hone from Brush research.

It is a 800 grit Levigated Alumina compound. there specks for the surface finish are RA 3-10 (.05-.2 micrometer)

My intent is to polish the cylinder. Don't know how it will work till I give it a whirl. for $32 have nothing to lose testing it on old liners.

Will give it a try this weekend.

David

We used a copper plug lap and diamond dust to lap more taper in the liners, also used a jig grinder with borazon carbide wheels to get them round and add taper. You might want to consider using a support sleeve around the liner when working it.

John

My thinking is to give the piston a better chance of seating good.

- Joined

- Apr 20, 2011

- Messages

- 2,079

Hi David,My intent with this is to just get a good surface finish. Not trying to change the tapper.Hi David,So to get back to the piston fit.

I have ordered a custom 29mm hone from Brush research.

It is a 800 grit Levigated Alumina compound. there specks for the surface finish are RA 3-10 (.05-.2 micrometer)

My intent is to polish the cylinder. Don't know how it will work till I give it a whirl. for $32 have nothing to lose testing it on old liners.

Will give it a try this weekend.

David

We used a copper plug lap and diamond dust to lap more taper in the liners, also used a jig grinder with borazon carbide wheels to get them round and add taper. You might want to consider using a support sleeve around the liner when working it.

John

My thinking is to give the piston a better chance of seating good.

If you get the surface too smooth it will take much longer to seat and break in, we found keeping them round was hard to do.

John

Similar threads

- Replies

- 37

- Views

- 6K

- Replies

- 1

- Views

- 877