- Joined

- Jan 2, 2006

- Messages

- 2,760

Can anyone give a quick explanation on why the newer brushless motors have three wires going into them ?

Is it wound like an alternator on a car is?

In a 3 phase delta configuration?

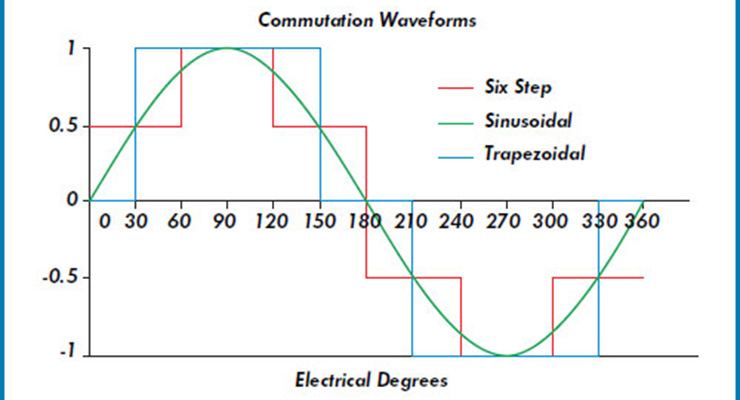

Any technical links to how the speed controllers convert the DC battery voltage to the input voltage for the motor windings would be appreciated!

Is it wound like an alternator on a car is?

In a 3 phase delta configuration?

Any technical links to how the speed controllers convert the DC battery voltage to the input voltage for the motor windings would be appreciated!