John Capps

Well-Known Member

- Joined

- Dec 9, 2005

- Messages

- 209

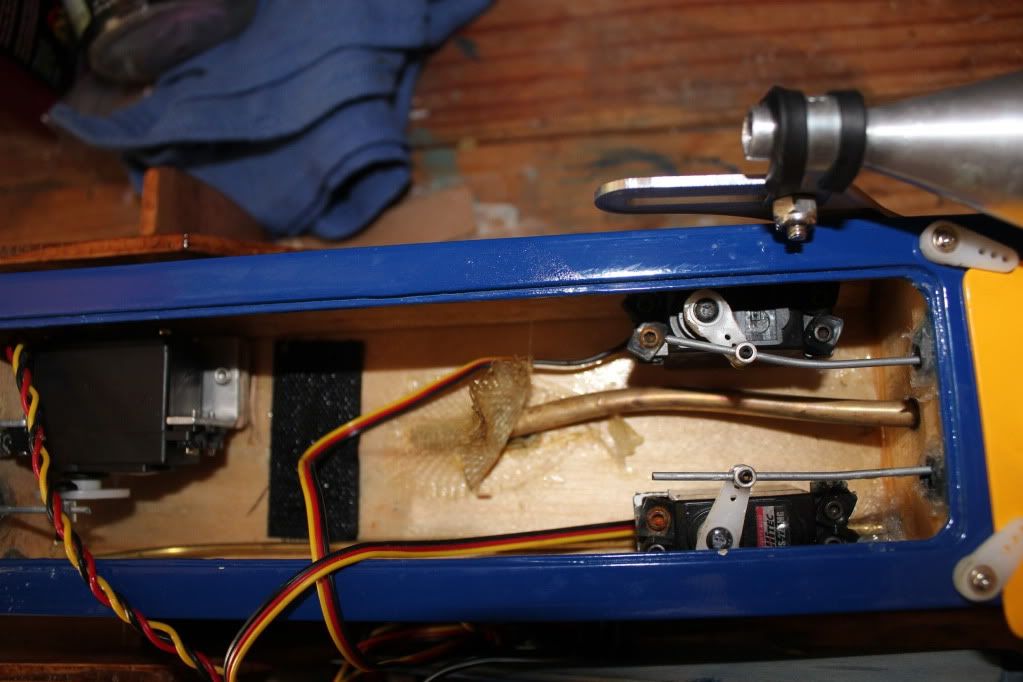

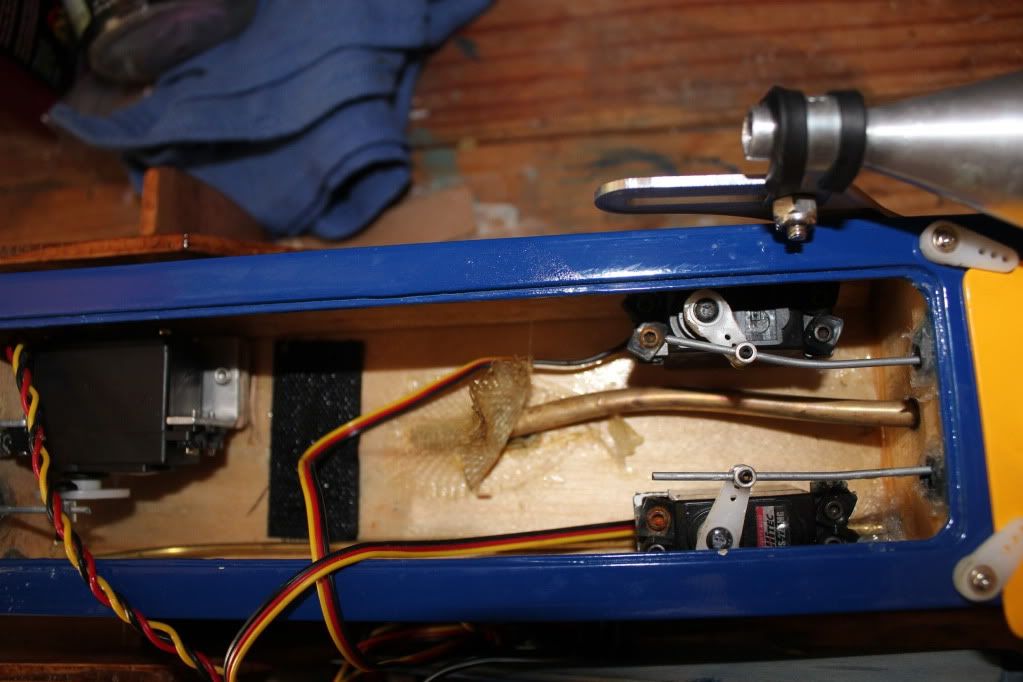

I was running the boat this weekend at the lake and my shaft tube got torn up. I know this has happened to others before but was just wondering what may have caused this. I grease the shaft after each use but maybe ran it too many times without greasing it. How ofter do you guys grease the shaft and what are you using for lubrication? I am leaving town tomorrow for vacation so hopefully I will get some insight so I can work on it when I return Saturday. Thanks in advance.