gratte-tout

Well-Known Member

- Joined

- Jan 28, 2008

- Messages

- 166

Hi all,

As my .21 twin starts to be performant, I take time to start the building of the 360HTB hull I bought there's few months ago.

It will be mounted with a special edition K&B, a 80 one, if you have informations about it, I'm interested, I don't know anything about this engine, almost the basic settingsof it.

Because a friend conviced me the interest of a trim system on such a hull, I decided to think about a simple system to angle the engine with my radio when necessary.

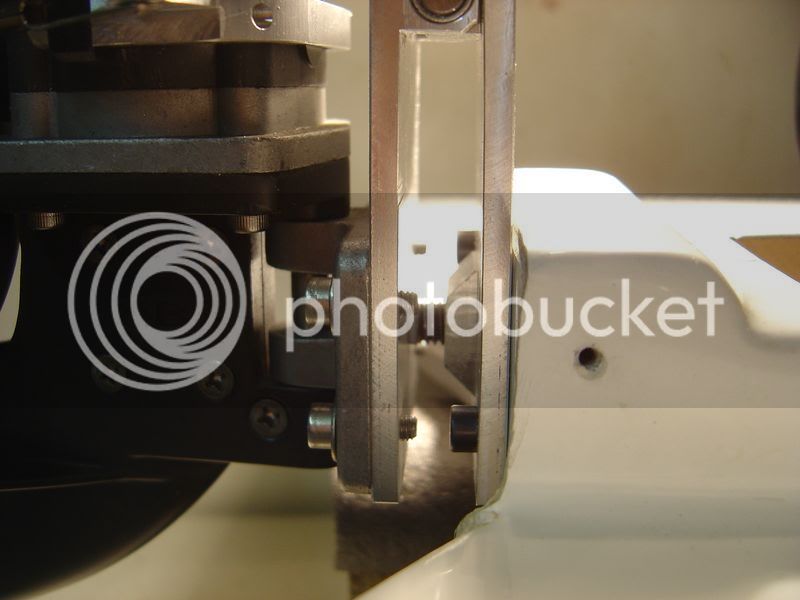

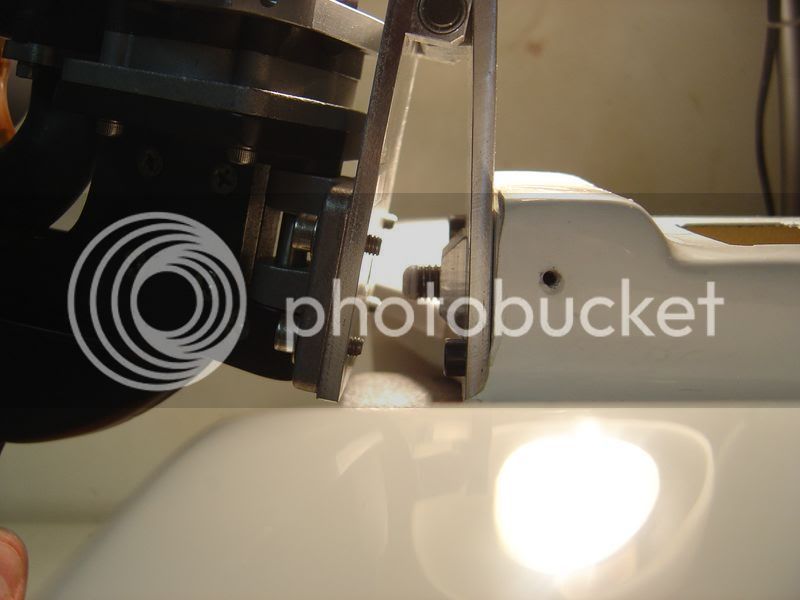

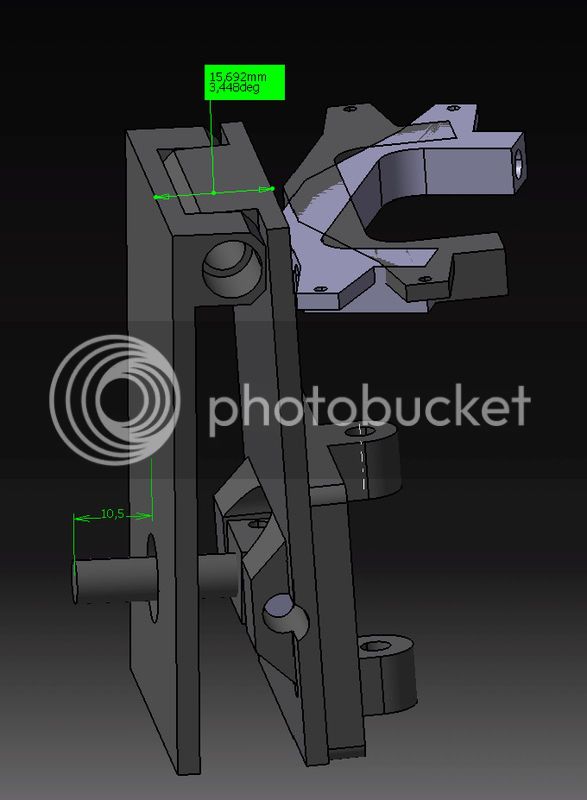

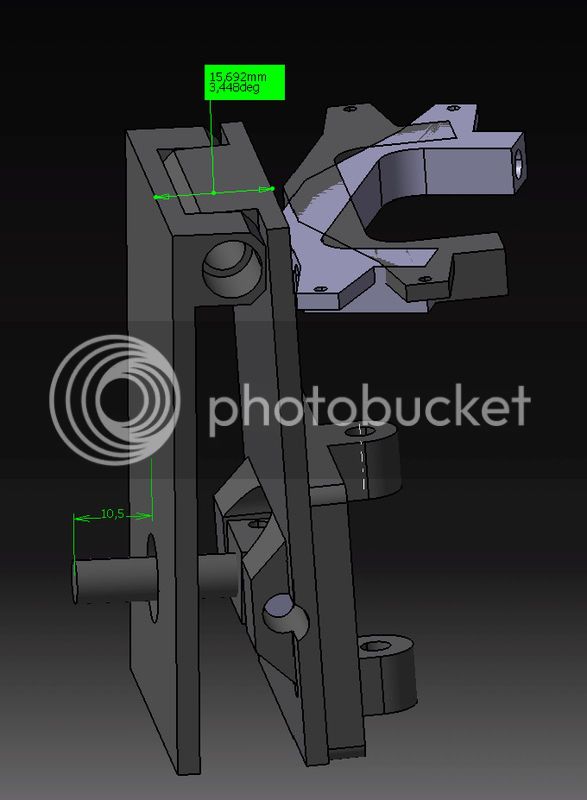

After triying to design as more simple as possible the system, I decided to use a bracket with a screw, moved with a sail servo like the Hitec HS855 (3.5 turns). When the servo is turning, the screw with a 1.5 mm pitch is pushing the bracket where the engine is screwed.

The two brackets are assembled so that when the engine is angled, the steering rods are not pushed or reverse. The rotation location of the two brackets is on the same plan than the steering rods.

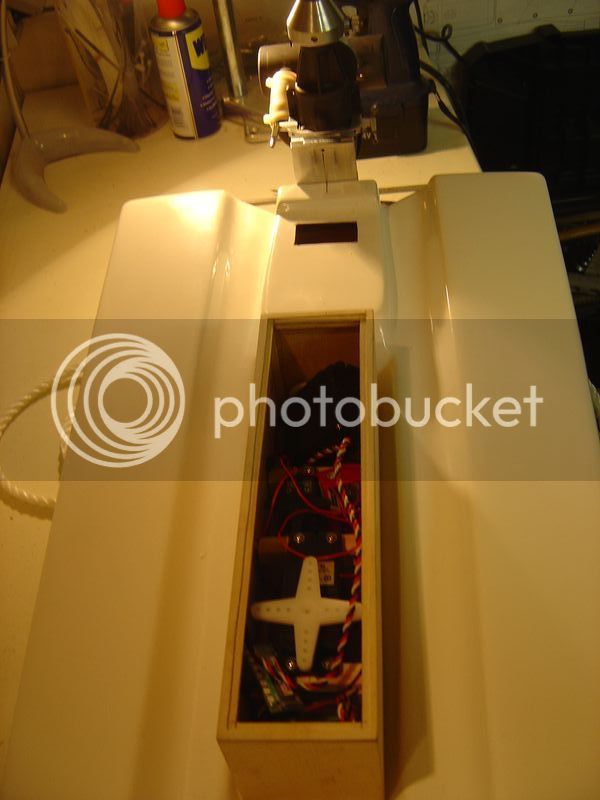

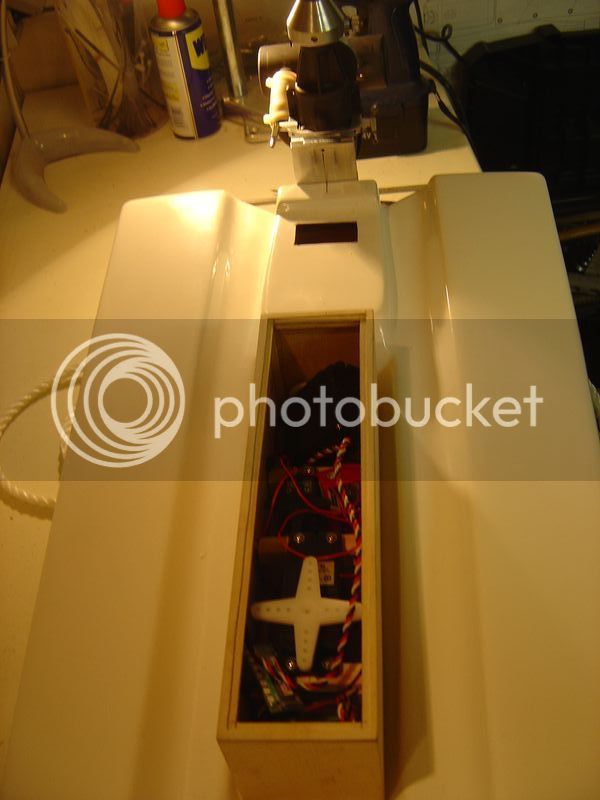

I had to built a new radio box, the one coming with the hull didn't allow to put another big servo, almost I don't wnat to put it on the same position than the steering one.

The old radio box with the servos I have to put :

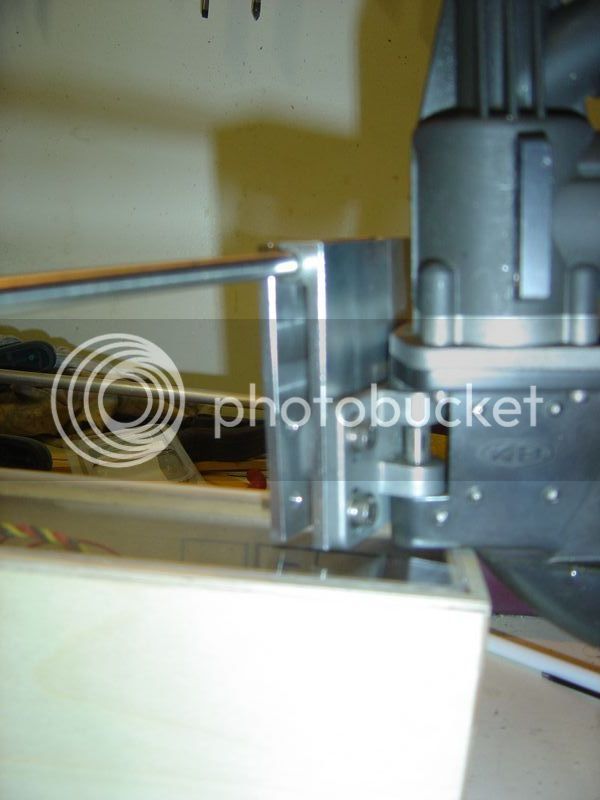

The designed trim system

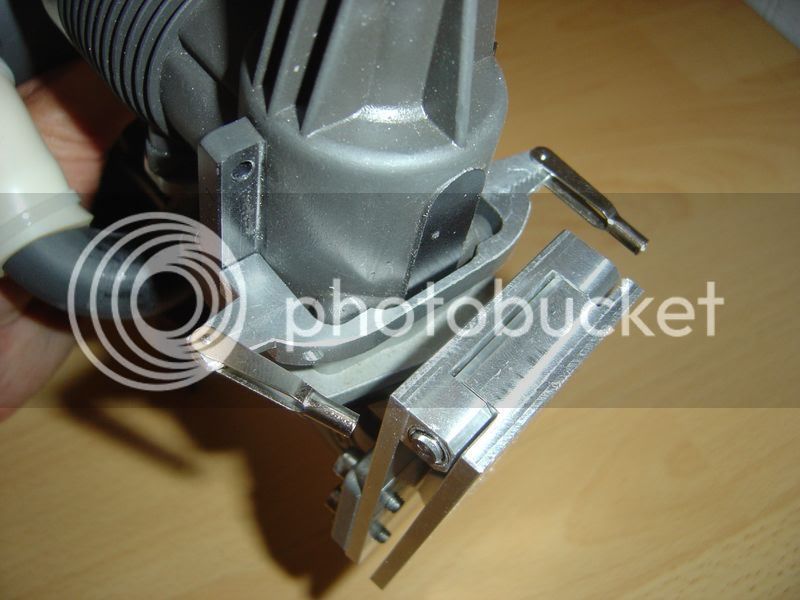

This picture showed I had to machine a new steering bracket, the plastic one was not compatible with the trim brackets.

After CAD pictures, machining and gluying!

The new radio box :

.

As my .21 twin starts to be performant, I take time to start the building of the 360HTB hull I bought there's few months ago.

It will be mounted with a special edition K&B, a 80 one, if you have informations about it, I'm interested, I don't know anything about this engine, almost the basic settingsof it.

Because a friend conviced me the interest of a trim system on such a hull, I decided to think about a simple system to angle the engine with my radio when necessary.

After triying to design as more simple as possible the system, I decided to use a bracket with a screw, moved with a sail servo like the Hitec HS855 (3.5 turns). When the servo is turning, the screw with a 1.5 mm pitch is pushing the bracket where the engine is screwed.

The two brackets are assembled so that when the engine is angled, the steering rods are not pushed or reverse. The rotation location of the two brackets is on the same plan than the steering rods.

I had to built a new radio box, the one coming with the hull didn't allow to put another big servo, almost I don't wnat to put it on the same position than the steering one.

The old radio box with the servos I have to put :

The designed trim system

This picture showed I had to machine a new steering bracket, the plastic one was not compatible with the trim brackets.

After CAD pictures, machining and gluying!

The new radio box :

.

Last edited by a moderator: