pda75

Well-Known Member

- Joined

- Jun 2, 2007

- Messages

- 83

Hi

I have started a new rigger : many picture are here.

http://www.offshore-rc.com/forum/index.php?showtopic=21130&view=getnewpost&hl=&fromsearch=1

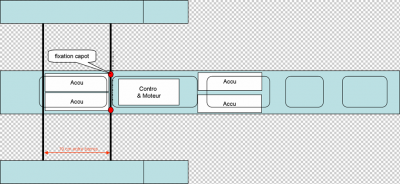

It a 1,25 meter (~50 inch) long rigger about 16 lbz. It will be powered with a lehner 3060/8 with lipo 10S2P. ESC is an YGE200 Navy. EPR 5000 means in french "nuclear plant 5000" and in english "Electric Propulsion Rigger 5000 watt"

the boat is designed for oval racing with 90 nitro riggers

Feel free to help me as I have not found many similar projects

cheers

Pierre

I have started a new rigger : many picture are here.

http://www.offshore-rc.com/forum/index.php?showtopic=21130&view=getnewpost&hl=&fromsearch=1

It a 1,25 meter (~50 inch) long rigger about 16 lbz. It will be powered with a lehner 3060/8 with lipo 10S2P. ESC is an YGE200 Navy. EPR 5000 means in french "nuclear plant 5000" and in english "Electric Propulsion Rigger 5000 watt"

the boat is designed for oval racing with 90 nitro riggers

Feel free to help me as I have not found many similar projects

cheers

Pierre

Last edited by a moderator: