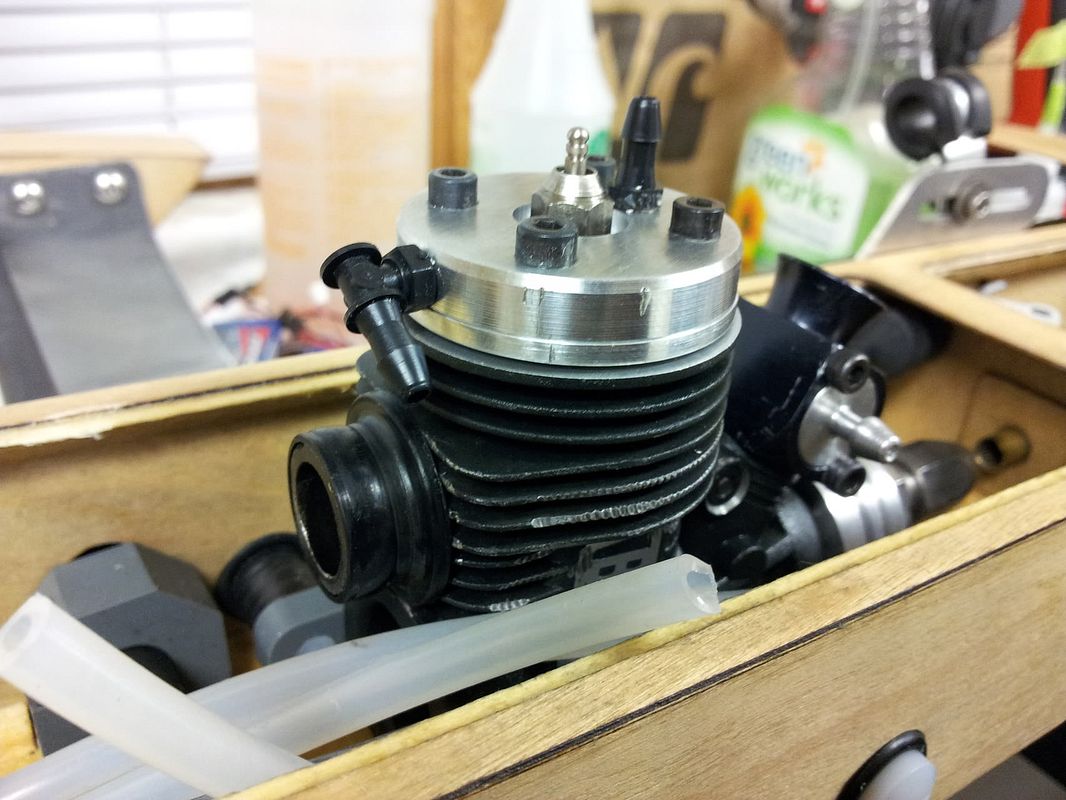

.020" to .030" is where all my water outlets are. depends on the engine & hull. riggers & my k&b ob's run down near the .020" end. riggers run under less load when set up correctly, & need less cooling because of it. pushing a mono thru the water requires more water, imo. at least that's the way it works on my hulls.i prefer to restrict the water at the outlet. restricting at the inlet & having a larger outlet hole than the restricted inlet can cause the cooling system to not fill completely. that can cause air pockets & hot spots, leading to detonation. i have never had a water line come off doing it this way, even on my screaming fast jae .21. i just make sure i use large enough fittings & small enough tubing that it is a TIGHT fit. also, drill your outlet hole (if you do it this way) right next to the original outlet, so you get full circulation. start small, it's much easier to enlarge a hole than shrink it.........remember that we're trying to get temps up to 180 to 220 degrees. want a comparison? run your car down the highway for 10 miles, then stop & pop the hood & lay your hand on the radiator (be careful, it WILL be hot). that's 180 - 220. waaaay hotter than most folks believe. once you do that, you might realize that your boats are running much cooler than they should. temp guns are useful, but just slowing down coming in to shore & the few second delay in getting a temp reading can mean 20+ degrees less than running down the straights at wot. i've used one of the venom battery moniters that record temps, i was surprised at the differance. on my nitro buggies, i can get a temp reading much quicker, so i know the venom reads fairly accurately. what i read on the beach & what i recorded on the pond have been as much as 30 degrees different...........proper temps mean more power & longer engine life!