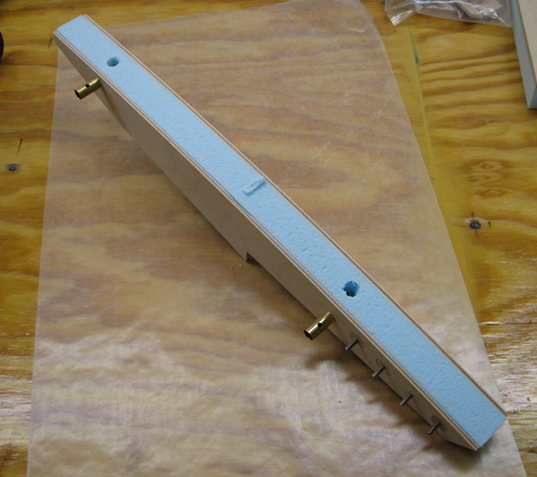

MIke sorry to hear that and Todd on here had given me a heads up before i built mine so i went with 5/16 hollow boom tubes and used brass in the sponsons the same way that zip designed the 21.I had decided that this was a better design well before the 21 had come out.

During the build it is much easier to do obviously but if i were you i would get some 5/16 hollow CF rods and the K&S brass tubing that it goes in drill out the aluminum in the sponsons and go clear throug as well as the holes in the tub and do what i did.

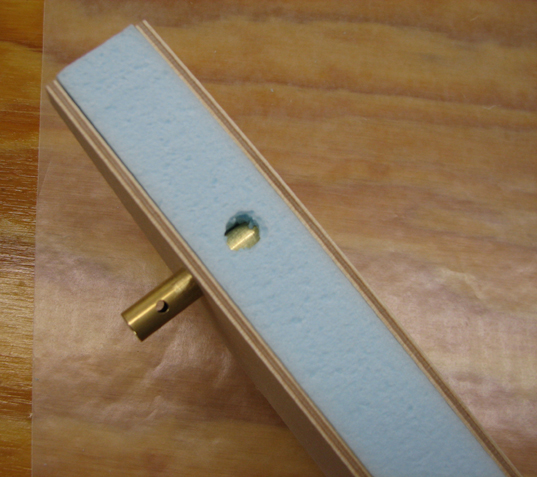

If you do make sure you slot the brass to allow the collars to clamp on the brass and squeeze the cf rods.

YOu can recess the foam inside the sponson to alow you to get more epoxy in there and when the new tubes roughed up tubes like ron mentioned are installed you can rotate the brass so it get coated with glue.You can also go in through the top or the bottom with a drill and get some glue in there that way.

If you do not go all the waythrough with the aluminum or brass you will not solve your problem

If you continue to use the solid 1/4 shafts you will probablly damage your boat before the tubes break.IMHO.

Lots of people are using them but how many are racing, having a crash or hitting a bouy really hard ????

I have already seen a rigger with the tub ripped out because the booms never borke first

Now is tha time the season is just starting for you.