Grayson,

I only use the Formeco TNC tach for measuring any width propeller blade. This tach is also preferred by many pylon racers for the final setting of the engines RPM at the start line.

Jim Allen

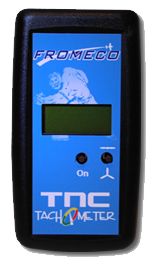

TNC Tachometer

Regular price$150.00

Default Title - Sold out/Call for Availability SOLD OUT/CALL FOR AVAILABILITY

In the mid-70's, an engineer named Tony Criscimagna invented a tachometer which still stands as one of the best in existence. Soon after, Tony started a business and sold thousands of these excellent tachometers under the trade name "TNC" (his initials).

Skyborn Electronics (Powerflite) acquired the TNC from Tony around 2003, and continued to build the original design. Faced with the obsolescence of some critical components, Skyborn started to work on updating the design, but never completed this process.

July 2005:

FROMECO Scale Avionics was presented with the welcome opportunity to acquire the TNC tachometer! We are exceptionally pleased to be able to reintroduce this outstanding product to the RC modeler community.

What we ChangedProcessing: The FROMECO TNC's "brain" has been totally revised, incorporating current microprocessor technology for 0.05% accuracy and improved functionality.

Durability: FROMECO has re-engineered the tachometer's packaging. The FROMECO TNC fully protects the sensor element, has an integrated battery compartment, and is more resistant to damage.

ON/OFF control: The FROMECO TNC uses slider switch to turn the tachometer.

(Picture shows buttons, Now switches.)

High RPM hold: The revised tach displays both the current RPM and the highest RPM attained. There are 5 significant digits for each measurement, for easy reading.

Upgraded components: The new TNC uses an upgraded sensor element, easily capable of obtaining RPM measurements at 6 feet under most lighting conditions. The components have been upgraded to surface mount technology, for reduced size and better durability.

What we didn't ChangeRange: The new TNC uses the same optical front end (the part that detects the propeller blades) as the original, with only minor revision for modernization of the parts. A well-proven design!

Performance: The readings are just as solid as one could expect from a TNC, even though the processing method is different. The range is still excellent. The accuracy is still outstanding. We continually compared the revised design with about a half-dozen of the originals, to make sure the new one meets or exceeds the standard set by the original TNC tachometer.

"The Name": Thanks, Tony, for a great tachometer! Also thanks to Skyborn Electronics, for allowing us to bring this tool back to the RC community!