PaulHail

Well-Known Member

- Joined

- Mar 30, 2017

- Messages

- 357

Again you need to look at the whole picture and realize intake and exhaust durations are just part of the picture and going with overly long durations can lead to a slower engine due to a lack of ability to pull the prop off the beach.

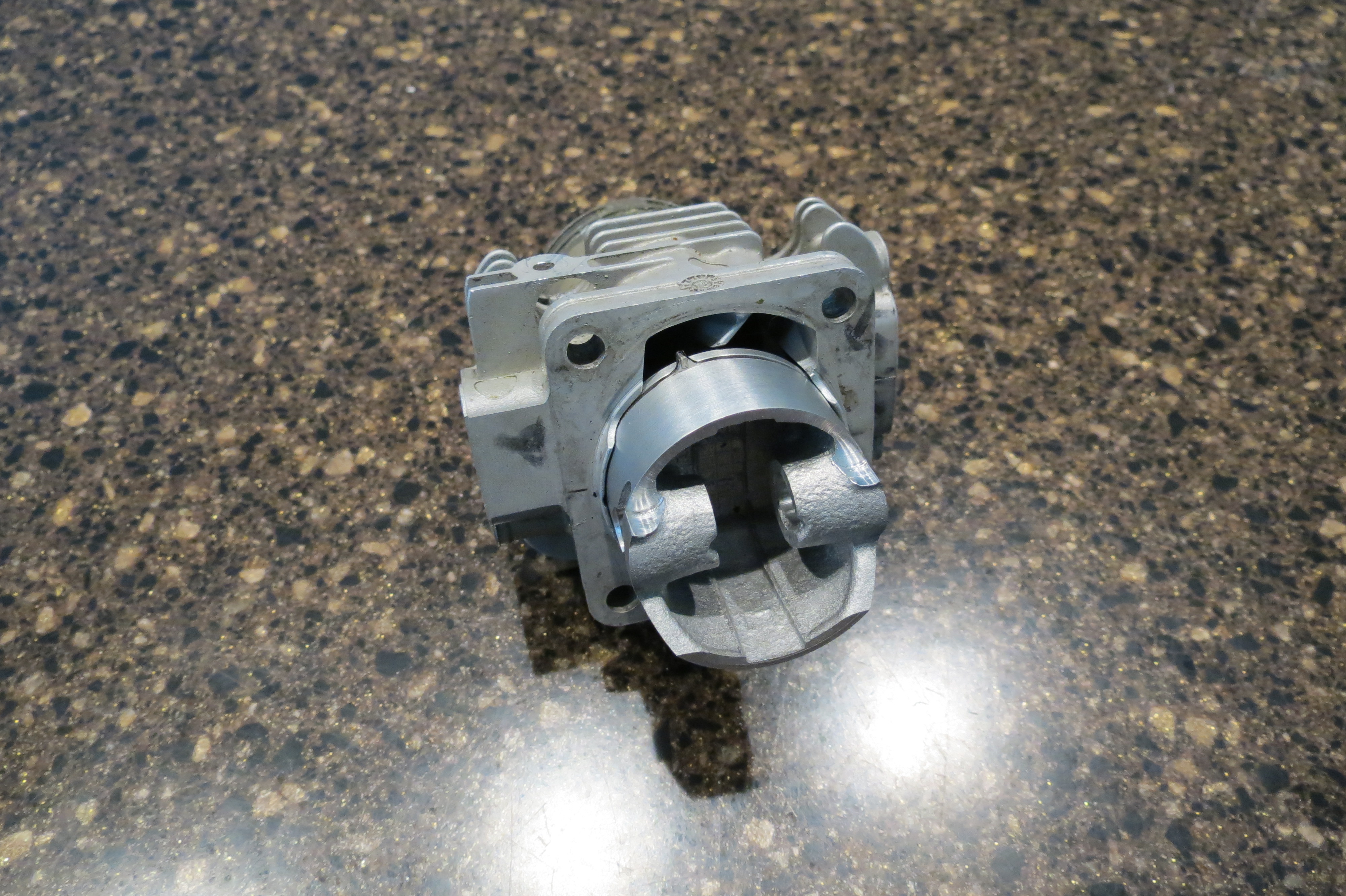

As an aside, I found it interesting the in kart racing one of the international classes was for a single cylinder 100cc engine with exhaust duration limited to 177 deg and that was in place for decades. Engines in that class peaked at 14,000 rpm in the 70's and 80's. In the 1993 homologation, the new engines were able to rev to 17,000 rpm. By early 2000 when the 100cc class was replaced with a 125cc class, the engines were turning 20,000 rpm. The only significant change in the port layout was going from a dual exhaust port, two transfers and a single boost to a configuration of single large exhaust with two small side ports above the transfers, two transfers and a single boost.

So with what might be considered relatively mild port durations, i.e. exhaust in the +/- 180 deg range, tremendous power can be developed in a two stroke, but that requires proper development of how air and fuel flows internally in the engine as well as balancing out the transfer and boost durations, and the intake opening and closing.

As an aside, I found it interesting the in kart racing one of the international classes was for a single cylinder 100cc engine with exhaust duration limited to 177 deg and that was in place for decades. Engines in that class peaked at 14,000 rpm in the 70's and 80's. In the 1993 homologation, the new engines were able to rev to 17,000 rpm. By early 2000 when the 100cc class was replaced with a 125cc class, the engines were turning 20,000 rpm. The only significant change in the port layout was going from a dual exhaust port, two transfers and a single boost to a configuration of single large exhaust with two small side ports above the transfers, two transfers and a single boost.

So with what might be considered relatively mild port durations, i.e. exhaust in the +/- 180 deg range, tremendous power can be developed in a two stroke, but that requires proper development of how air and fuel flows internally in the engine as well as balancing out the transfer and boost durations, and the intake opening and closing.