Mark Bullard

Well-Known Member

- Joined

- Jan 26, 2004

- Messages

- 1,781

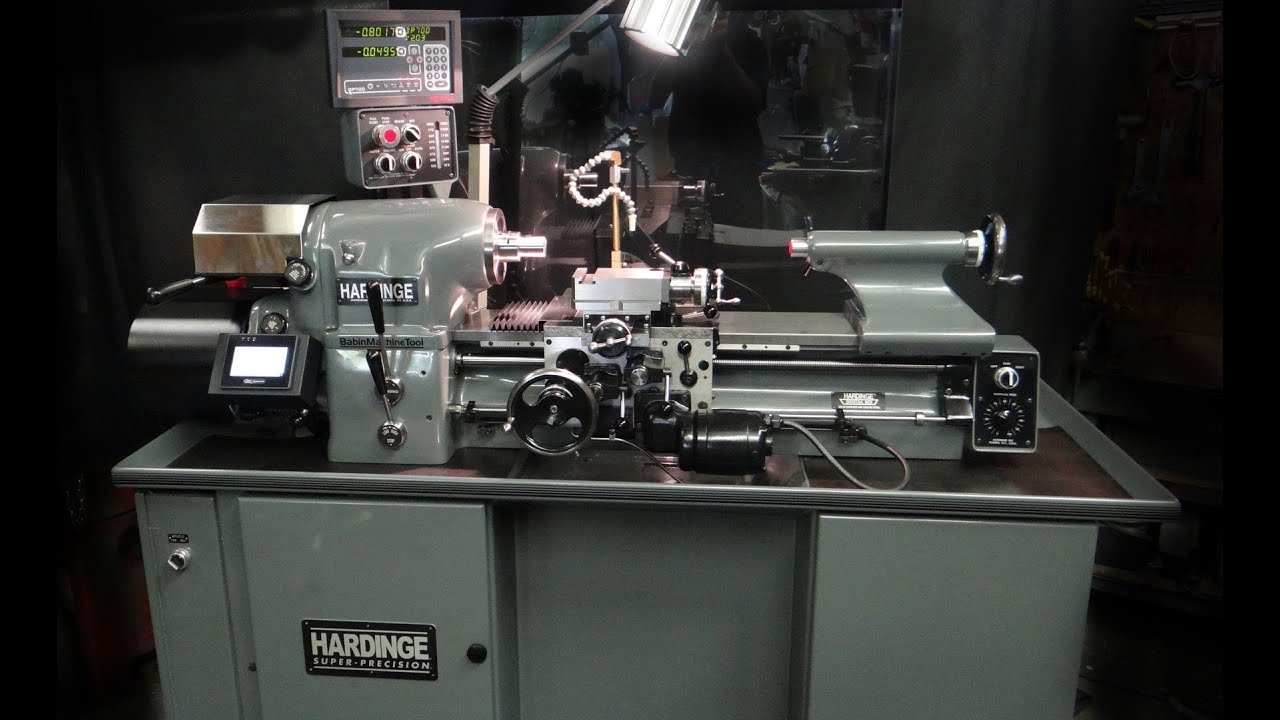

Lohring, It still looks good for its age. A little cleanup and paint will make them look nice. And holding tolerance in 12" is as good as any. But $2500 may be high for scrap price. Scrap prices are only at about .10 cents a 100 pounds. The only problem with scraping a lathe the scrap yard will not take it. They can not tear it up into small pieces. Here are some pictures of lathes that I have bought at scrap prices and brought back to life.

Here is a Bullard VTL that I bought for scrap. Paid $10,000 and spend $15,000 to rebuild. First three pictures

Here is a Southbend That I bought for $1500 and spend about $2000 to rebuild. Other pictures.

Here is a Bullard VTL that I bought for scrap. Paid $10,000 and spend $15,000 to rebuild. First three pictures

Here is a Southbend That I bought for $1500 and spend about $2000 to rebuild. Other pictures.

Last edited by a moderator: