I haven't been following your whole thread completely but I just remembered your using the R RCMK block. The front end of those cases is capped off.

The rubber type 2L belts won't work with a captured belt and nitro fuel. Black mess of goo everywhere.

The Speedmaster pulley for the collet end is smaller than the Zipp Kit I believe.

Edit: just saw you discussed that already. Harry is out or hasn't made new one for their new collet yet.

If the pulley won't fit. What are you using for a flywheel ? It isn't going to go without decent amount of flywheel weight.

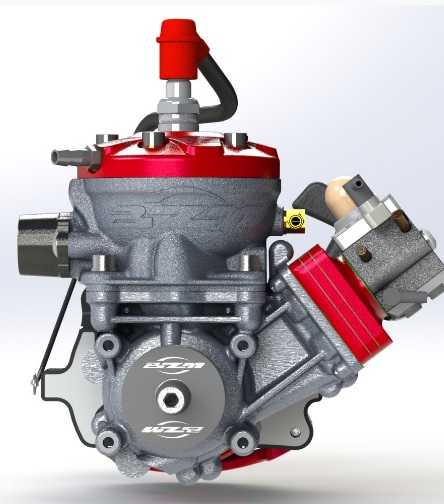

Is this the engine your working on. With a TK full circle crank you could get away with just a pulley for flywheel weight but still might not launch very easily. With a porkchop crank you would for sure need more flywheel weight.

Machine off the capped up end and put the pulley/flywheel weight at the front. Just have to swap the outer bearing for a sealed bearing if using a straight ended non tapered crank. If ends are tapered then replace that with a rubber seal. Then pulley can be in front and the rubber belt would not be captured on the pulley so nitro wouldn't get to it. May not be enough room though to get to pulley with the belt with the carb in the way I realize too.

I guess you are back to the collet pulley idea but finding a belt compatible with nitro that won't just break. Don't know what the 8mm ebay belts are you referred to. Maybe ? You might wanna just turn up a pulley to fit the Speed Master collet out of brass with some thickness for the weight you are going to need for sure. It must have some more inertia to start, idle and pull away from the beach.