You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Build Your Own LED Start Clock....

- Thread starter Blackout

- Start date

Help Support Intlwaters:

This site may earn a commission from merchant affiliate

links, including eBay, Amazon, and others.

Blackout

Well-Known Member

- Joined

- Sep 10, 2008

- Messages

- 1,610

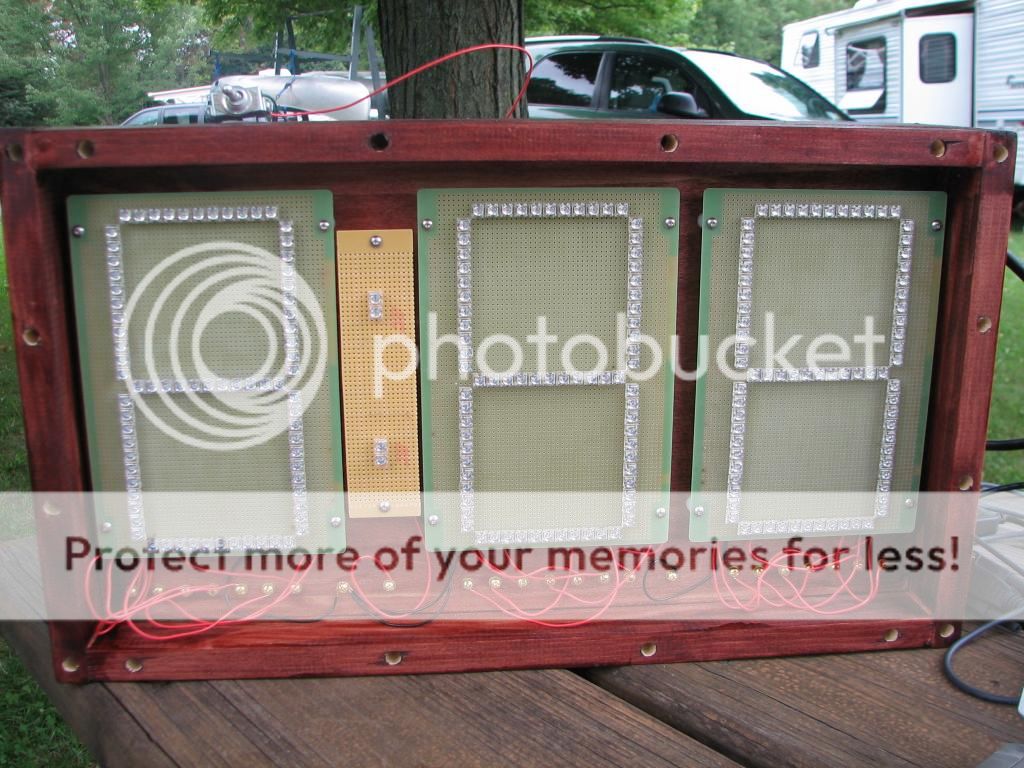

Digits are only 7.5" high, but can be seen at 150 plus feet. There are 11 LEDs per digit segment. The digits can easily be seen in direct sunlight. The brain is a CLICK programmable logic controller. Below are some details and more details will follow with video too.

5mm Red High Flux LEDs, part number HF5-R5590, at $.20 each.

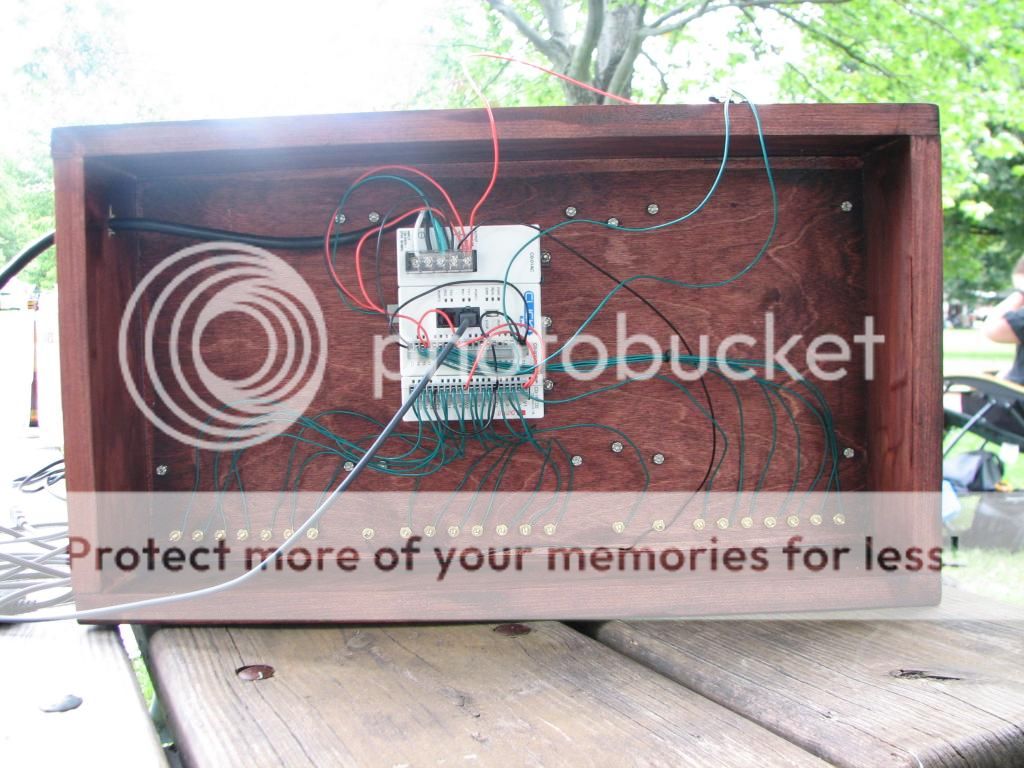

C0-00DD2-D Click PLC, 8 DC Input/6 Sourcing DC Output at $69.

C0-16TD2 16-Point Sourcing DC Output Module at $45 each.

www.automationdirect.com

www.superbrightleds.com

5mm Red High Flux LEDs, part number HF5-R5590, at $.20 each.

C0-00DD2-D Click PLC, 8 DC Input/6 Sourcing DC Output at $69.

C0-16TD2 16-Point Sourcing DC Output Module at $45 each.

www.automationdirect.com

www.superbrightleds.com

Blackout

Well-Known Member

- Joined

- Sep 10, 2008

- Messages

- 1,610

The red glare is only seen from the video. The display looks better in person.

The start is the "0:00". The ten second "0" digit is lagging a little at the start, but that is easy to tweak. Be assured, the 9 sec to 0 sec countdown is stepped a perfect 1000ms. The first two digits are adjusted to match the third digit. They are off a 50ms or so from processing speeds I think. So I tweaked it in the Ladder Logic program. Each digit is controlled by a separate drum sequencer in the program, so that could be what produces the small lag.

Ladder Logic is used to program PLCs. The software is a free download for Click PLCs. I can e-mail the program to anyone interested. I'm working on a FE 1:00 count down now.

The start is the "0:00". The ten second "0" digit is lagging a little at the start, but that is easy to tweak. Be assured, the 9 sec to 0 sec countdown is stepped a perfect 1000ms. The first two digits are adjusted to match the third digit. They are off a 50ms or so from processing speeds I think. So I tweaked it in the Ladder Logic program. Each digit is controlled by a separate drum sequencer in the program, so that could be what produces the small lag.

Ladder Logic is used to program PLCs. The software is a free download for Click PLCs. I can e-mail the program to anyone interested. I'm working on a FE 1:00 count down now.

Last edited by a moderator:

Joe Petro

Well-Known Member

- Joined

- Sep 10, 2003

- Messages

- 368

Excellent!

Is that CLICK sinking all the current? 231 LED's @ 100ma each is over 23 amps at full display (8:88).

I understand that it will almost always be lower, but is still must be capable...

Unless you use a chopper circuit?

Can that CLICK be programmed for stand alone use with relay closures or logic so that a PC is not needed?

Very interesting...

Is that CLICK sinking all the current? 231 LED's @ 100ma each is over 23 amps at full display (8:88).

I understand that it will almost always be lower, but is still must be capable...

Unless you use a chopper circuit?

Can that CLICK be programmed for stand alone use with relay closures or logic so that a PC is not needed?

Very interesting...

Blackout

Well-Known Member

- Joined

- Sep 10, 2008

- Messages

- 1,610

The Click PLC is carrying all the current. Each output is rated at .1 amps at 24 volts or 2.4 watts. But Click does sell relayed output modules to handle 1 amp and 7 amp, but the price goes up. Each LED draws .02 amps at 2.2 volts or .044 watts. Multiplied by eleven LED's per digit segment and that is .484 watts per output. That is well under the 2.4 watts max. Eleven LEDs are wired in series to run at 24 volts with no resisters. The colon uses 4 LEDs total so a 750 ohm resistor brings the voltage down to around 9 volts.Excellent!

Is that CLICK sinking all the current? 231 LED's @ 100ma each is over 23 amps at full display (8:88).

I understand that it will almost always be lower, but is still must be capable...

Unless you use a chopper circuit?

Can that CLICK be programmed for stand alone use with relay closures or logic so that a PC is not needed?

Very interesting...

- Joined

- Oct 19, 2006

- Messages

- 1,467

can a start horn/buzzer be incorporated?

Don Brown

Well-Known Member

- Joined

- Jul 14, 2007

- Messages

- 595

[SIZE=12pt]Looks like you have a good start.[/SIZE]

[SIZE=12pt]Have you read what the IMPBA Rule Book says about digital starting clocks? It talks about clock operation, digit size and color.[/SIZE]

[SIZE=12pt]I have worked with this type of PLC Controllers used on production lines. They will do some strange things when they are operated outside their comfort zone. Their max operating temp is 140 deg F. and[/SIZE] a humidity range of 30 – 95 % (non-condensing). What might work in New York might not work in other parts of the country.

[SIZE=12pt]After years of designing and building electronic circuits, I have learned, if possible, to always use components that are rated at least 105 deg C. and that are not sensitive to humidity changes.[/SIZE]

[SIZE=12pt]DonB[/SIZE]

[SIZE=12pt]Have you read what the IMPBA Rule Book says about digital starting clocks? It talks about clock operation, digit size and color.[/SIZE]

[SIZE=12pt]I have worked with this type of PLC Controllers used on production lines. They will do some strange things when they are operated outside their comfort zone. Their max operating temp is 140 deg F. and[/SIZE] a humidity range of 30 – 95 % (non-condensing). What might work in New York might not work in other parts of the country.

[SIZE=12pt]After years of designing and building electronic circuits, I have learned, if possible, to always use components that are rated at least 105 deg C. and that are not sensitive to humidity changes.[/SIZE]

[SIZE=12pt]DonB[/SIZE]

Blackout

Well-Known Member

- Joined

- Sep 10, 2008

- Messages

- 1,610

Yes. Another output module would need to be added as the outputs are maxed out right now.can a start horn/buzzer be incorporated?

Blackout

Well-Known Member

- Joined

- Sep 10, 2008

- Messages

- 1,610

Yes, I am aware of the IMPBA rules.[SIZE=12pt]Looks like you have a good start.[/SIZE]

[SIZE=12pt]Have you read what the IMPBA Rule Book says about digital starting clocks? It talks about clock operation, digit size and color.[/SIZE]

[SIZE=12pt]I have worked with this type of PLC Controllers used on production lines. They will do some strange things when they are operated outside their comfort zone. Their max operating temp is 140 deg F. and[/SIZE] a humidity range of 30 – 95 % (non-condensing). What might work in New York might not work in other parts of the country.

[SIZE=12pt]After years of designing and building electronic circuits, I have learned, if possible, to always use components that are rated at least 105 deg C. and that are not sensitive to humidity changes.[/SIZE]

[SIZE=12pt]DonB[/SIZE]

The builder is free to build with larger digits. I may this winter.

Thanks for the heads up on the heat issue. It was something that I had thought about.

Man that is sweet. And look it only took 4 beers while he was on vacation

Blackout

Well-Known Member

- Joined

- Sep 10, 2008

- Messages

- 1,610

You surely could write a Ladder Logic program to do that. I had no experience with Ladder Logic, but learned the basics with YouTube videos and using the help section in the software. I did have experience with Basic, but not sure that really helped. Might of actually hindered because Ladder Logic is quite different to standard program writing.Would love a simple LED display to show the current heat number.

- Joined

- Oct 19, 2006

- Messages

- 1,467

driftwood model boat club has a digital heat board, actually 2 . goes 1 to 99 then we start over. we purchased them online as "take a number" work really well, if you can keep another function on your mind while in the tower. they forward and reverse if you hit the button accidentally. cuts down on "what heat r we on?'' if you can "train " the contestants. lol requires 120 v to operate

How big were the numbers and how much did it set you back? If I had a nickle every time someone asked me what heat we were on (right after I annouced it on the PA), I could afford a nice one really quick. LOL Ebay has a 3 digit one with 8" numbes for $400 (ouch). I also saw a 6" version for a bit over $200. I wouldnt mind building my own but wouldnt know where to start.

Last edited by a moderator:

Blackout

Well-Known Member

- Joined

- Sep 10, 2008

- Messages

- 1,610

One could program the heat number to advance on it's display automatically every time a start occurs. This is done on some clocks to read the next heat number when the race is occurring. But a separate display would be nice if you happened to want to know the next heat during race mill time.

This winter I will be trying this for our club's start clock. Our winters are very long and I need to stay busy....

This winter I will be trying this for our club's start clock. Our winters are very long and I need to stay busy....

Mark Bullard

Well-Known Member

- Joined

- Jan 26, 2004

- Messages

- 1,777

I have a program for my clock that uses the AutomationDirect/Koyo 205 PLC. It has start and stop/reset with a separate heat counter. The heat counter has a up and down inputs and increments one on the start of every heat. The program also has 30 sec jump from countdown. All the programs can be converted to the different Koyo PLC's. The I/O count is 1 - 8 point DC input module and 6 - 8 point relay module. I like using the relay module because they are the cheapest and you can use any voltage. My earlier clocks used a network bridge to connect a Ethernet connection for remote I/O between the console and the clock. This is very costly. I changed my clock this past year to use a cheap 2.4 four channel radio and wired the two of the channel across the buttons in the console. Tower sells a two position switch that plugs into a receiver channel that will control the inputs in the clock. Thus a cheap 2.4 wireless control for your clock. When I tested this type of 2.4 control the clock ran for 20 hours and never fell off. So I do not know what the battery life is. I have been using AutomationDirect for over twenty years.

I will be happy to send anyone a copy of the program and a drawing of how to setup a 2.4 radio to control it.

I also have segment boards that will take 30 LED's with their resistor for a 12 volt setup. Each board is 3 columns of 10 LED's make one segment. It take seven segments to make a digit about 12" x 7".

I will be happy to send anyone a copy of the program and a drawing of how to setup a 2.4 radio to control it.

I also have segment boards that will take 30 LED's with their resistor for a 12 volt setup. Each board is 3 columns of 10 LED's make one segment. It take seven segments to make a digit about 12" x 7".

- Joined

- Oct 19, 2006

- Messages

- 1,467

they are 8'' numbers and I think it was in the 200 range , maybe a little more. the 3 digits were 400 but I don't think it is worth the extra money. we place them facing each other but at each end of the tower, then they can be seen from where ever you are in he pits.

anthony scardina

Well-Known Member

- Joined

- Aug 27, 2008

- Messages

- 90

I was out watching the race in hobart today and their clock was a "flip" style segment display. Any time the clock was not in countdown mode, it displayed the heat number.

Similar threads

- Replies

- 5

- Views

- 1K

- Replies

- 32

- Views

- 3K